The benefits of manufacturing software

Reduction of waste and machine downtime

The adoption of a Manufacturing Execution System software primarily enables continuous monitoring of production activities, effectively minimising waste and machine downtime. Specifically, real-time tracking of process parameters and full traceability of operations allow for prompt intervention in case of anomalies, deviations, and inefficiencies. Furthermore, the integration between MES and ERP systems ensures alignment between planning and execution, promoting optimisation in the use of resources and materials. As a result, production becomes more stable, predictive, and quality-driven. Finally, for production managers, MES serves as a strategic tool to improve Overall Equipment Effectiveness (OEE) and thereby maximise plant performance.

-

Better control of the entire production chain

-

Improved production planning capability

-

More reactive response to unexpected events

-

Maintenance cost reduction

Fast and accurate production reporting

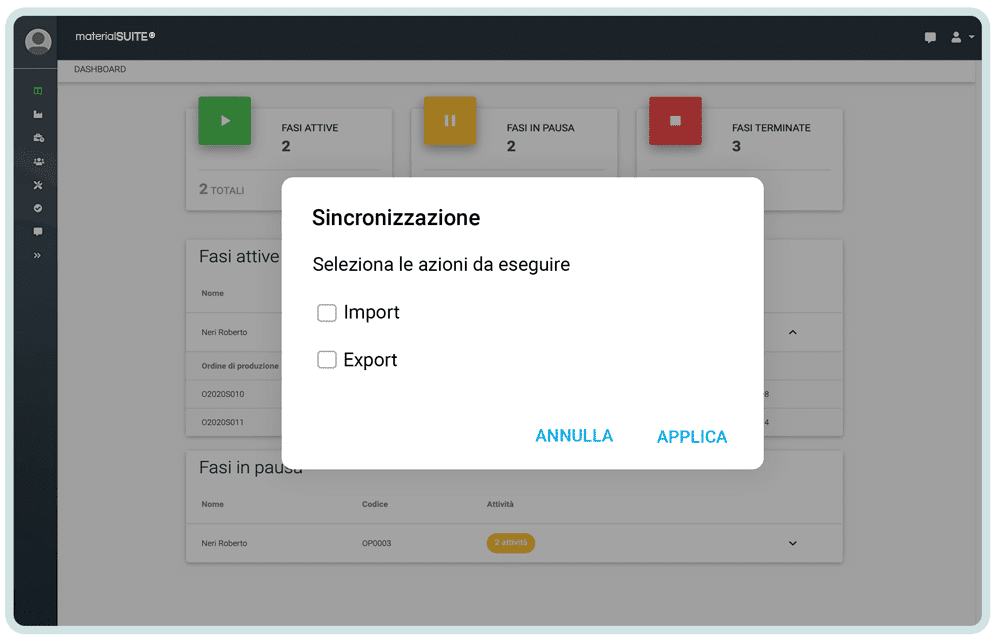

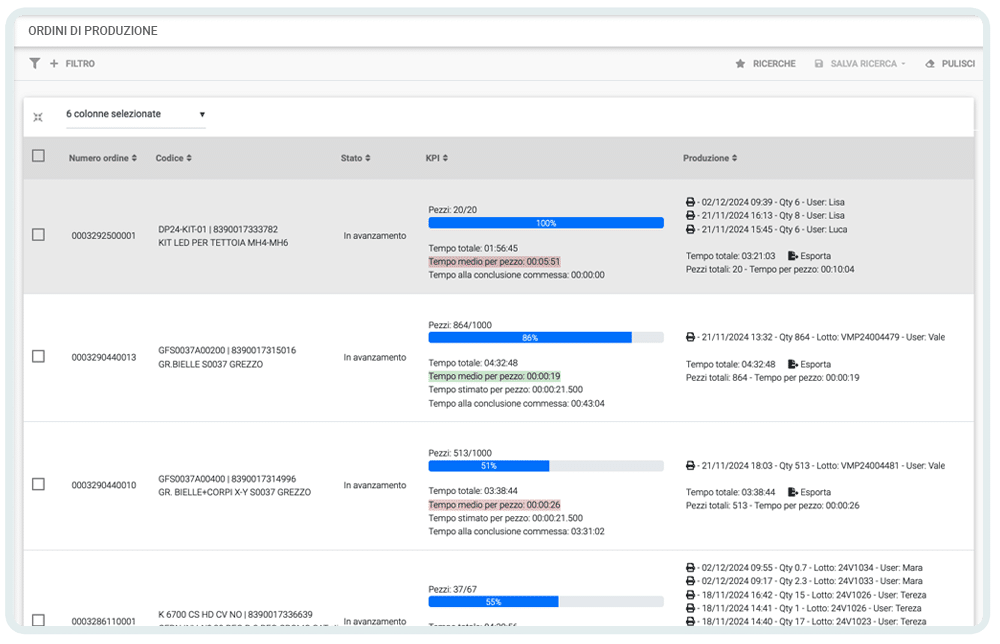

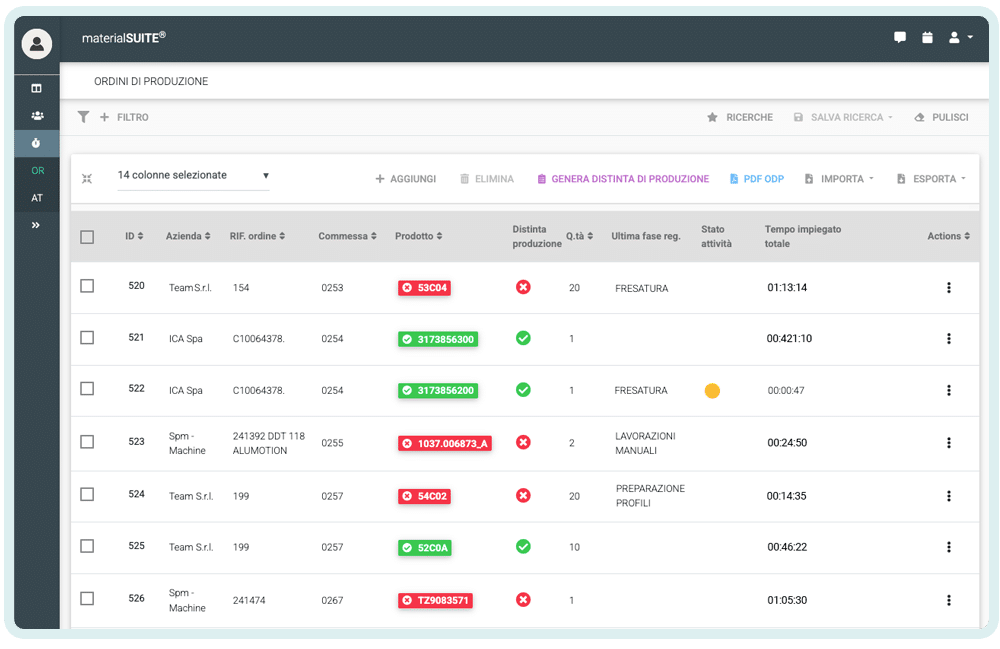

The manufacturing execution system software allows for precise and timely management of production progress and various internal manufacturing processes within the company. Specifically, operators can quickly record the status of “semi-finished” or “finished product” for the completed tasks, thereby ensuring fast and accurate production reporting. At the same time, supervisors have the ability to monitor the progress and completion level of orders in real time, which consequently simplifies the control of execution times. Additionally, adopting a customised manufacturing execution system tailored to specific production processes provides managers, supervisors, and operators with a practical tool that not only improves traceability but also helps to increase operational efficiency.

Moreover, this real-time visibility enables proactive decision-making, while seamless integration with existing systems ensures consistency across departments. Therefore, by implementing a manufacturing execution system, companies can streamline workflows, reduce errors, and ultimately enhance overall productivity.

-

Percentage update on order completition

-

"Bottleneck" reduction

-

Rapid imputation of the performed activities

-

Check the correspondence between the times used and estimates

Progress monitoring

The most frequent questions within a manufacturing plant typically concern the status of orders and jobs, as well as the ability to meet predetermined delivery dates. For this reason, having a manufacturing execution system for real-time production monitoring becomes essential.

Indeed, the manufacturing execution system software enables tracking of every stage of the production process, allowing for the timely identification of potential delays and, consequently, proactive intervention to optimise job management. In doing so, it ensures deadlines are met while simultaneously improving the reliability and efficiency of the entire production cycle.

-

Better control on launched activities

-

Production performance improvement

-

Accurate updates on orders/resources load

-

Delivery improvement

Production monitoring

Bridging the communication gap between offices and the production plant is made possible primarily thanks to manufacturing execution system software. These systems collect and process data generated by machines on the shop floor and make it available in real time to production managers and supervisors. Consequently, this fosters a continuous and effective flow of information between departments, effectively eliminating inefficiencies caused by the lack of up-to-date data.

Moreover, the ability to integrate with other existing enterprise management systems makes manufacturing execution systems indispensable tools for maintaining constant oversight of production inputs and outputs. As a result, companies can achieve more efficient resource management while ensuring optimisation of production and logistics processes on a global scale.

EXPERIENCES