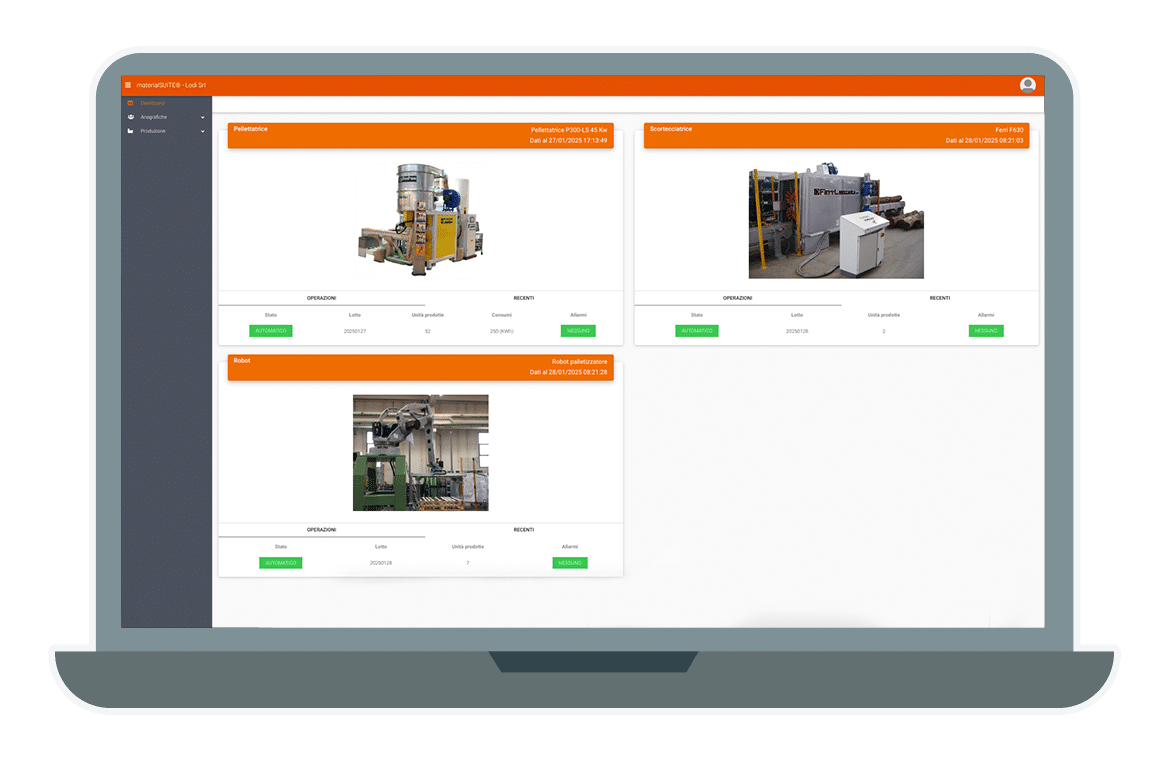

Smart machines 4.0 with materialBOX®

Connecting machines and software for advanced production control

Lodi Srl, a leading manufacturer of poplar wood packaging since 1962, is renowned for the quality of its products, using locally sourced raw materials and embracing a circular economy approach. Its automated production lines meet Industry 4.0 requirements for both manufacturing and palletizing.

Connecting machines with materialBOX® for smarter manufacturing

Optimize production with bidirectional data

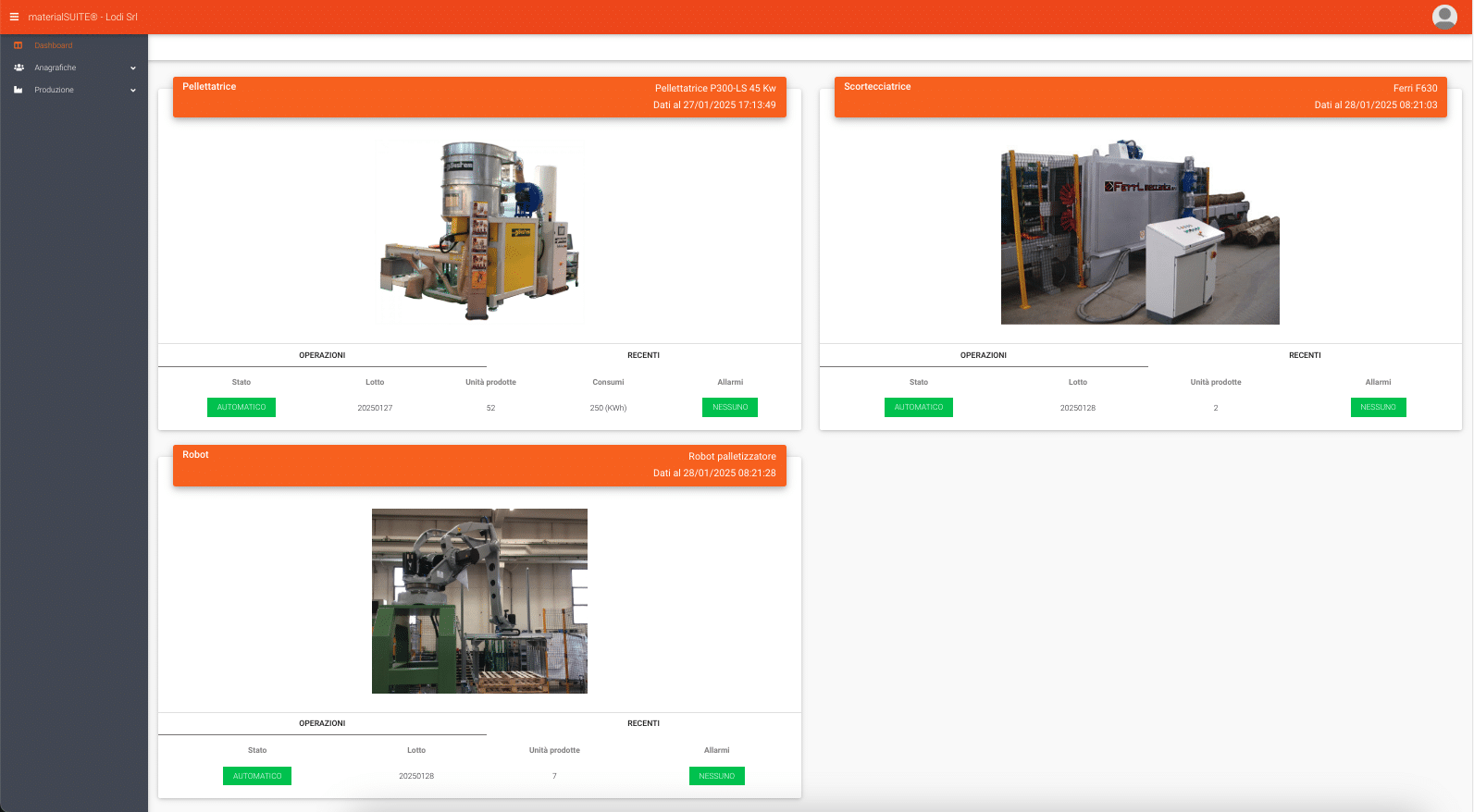

To optimize production, Lodi Srl aimed to enhance monitoring and efficiency across its industrial plant, aligned with Industry 4.0 principles. The key challenge was to collect and analyze real-time KPI data from its smart machines—such as pelletizers, debarkers, and robots—and turn them into actionable insights.

By implementing materialBOX®, our advanced Machine Software for monitoring and connectivity, Lodi Srl achieved seamless integration between its machines and enterprise management systems. This bidirectional data flow ensures constant, secure communication, enabling more accurate decision-making and modern, competitive production management.

materialBOX® is the ideal solution for companies looking to connect machines, monitor performance in real time, and improve production efficiency through a fully integrated Machine Software solution.

Objectives

Monitor machine KPIs in real time, ensure bidirectional communication between software and 4.0 machines, improve visibility and awareness of production performance

Solutions

We implemented materialBOX®, a Machine Software capable of connecting industrial machines to the company’s MES system, collecting and transmitting data using MODBUS for the pelletizer and PROFINET for the debarker and robot. With these advanced features, Lodi Srl can now analyze machine data and generate clear reports on resource usage and production times.

Benefits

Increased efficiency through real-time KPI visibility, reduced waste and optimized resource utilization, data-driven planning aligned with Industry 4.0 standards

Integrations