Analyse time and methods across your production processes

Optimise manual production phases through accurate human time tracking

Accurately understanding operator production times and methods is essential, especially for companies managing manual phases within the production cycle. Using the Overall Labor Effectiveness (OLE) metric, it becomes possible to effectively and precisely monitor operational performance. This allows the identification of inefficiencies and enables timely interventions to optimise production times. Moreover, this process helps increase overall productivity, thereby improving the efficiency of the entire production line all achievable through reliable time tracking software.

-

Rationalisation of production methods and processing time assignments

-

Precise definition of production costs through work and time keeping measurements

-

Better logistics management

-

Enhanced time control and potential production interruption identification

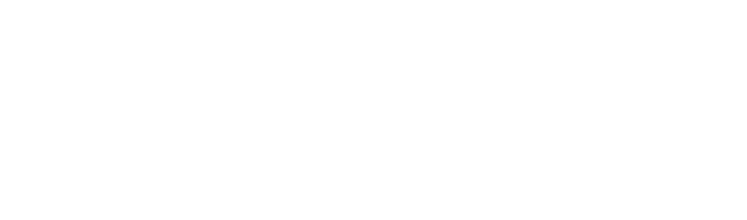

Time tracking software: simple, intuitive, and impactful

Thanks to time tracking software by materialSUITE®, companies can first and foremost conduct in-depth analyses of the real costs associated with manual activities, while simultaneously improving production time control.

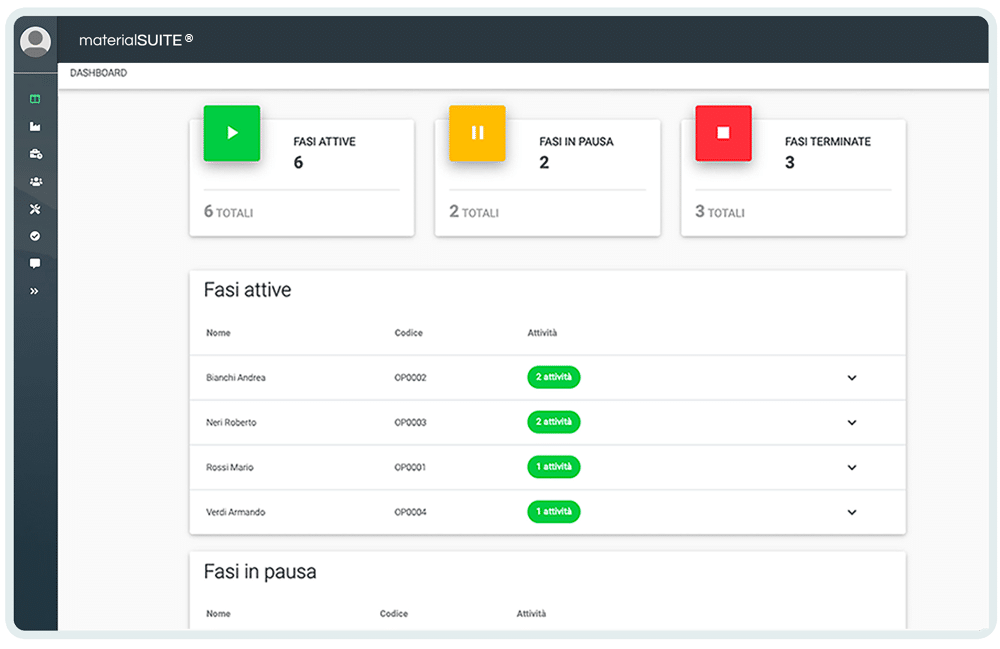

Each operator is equipped with an industrial mobile device, complete with a camera and internet connection, allowing them to instantly identify assigned tasks simply by scanning the activity’s barcode.

Furthermore, thanks to a job order structure organized by orders, phases, and production cycles, operators can easily access detailed information about the tasks to be performed. At this point, the super-timer is activated, enabling precise tracking of production times and formalising the start of the operational phase.

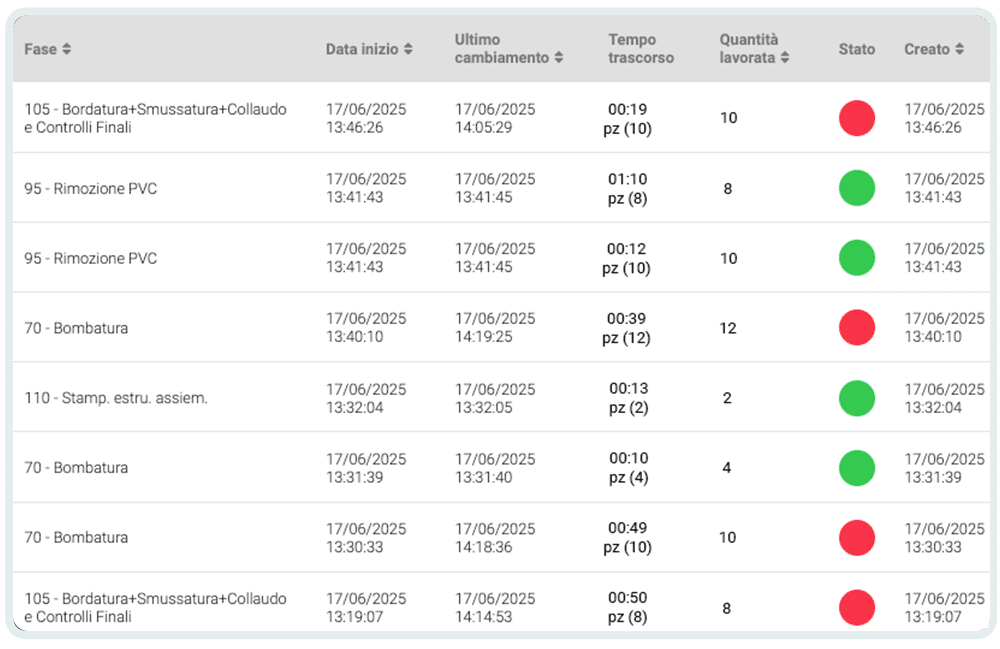

Once the activity is completed, the operator stops the timer and records the number of pieces processed, making the data immediately available for analysis. Meanwhile, the system updates the job progress status, providing the production manager with a real-time overview of operational efficiency all powered by our reliable time tracking software.

-

Faster exchange of information between employees and improved communication

-

Cost and waste reduction to streamline production

-

Identification and management of real manual processing times

-

Data collection on your production efficiency

Revenue growth comes from a clear understanding of production times

Labour time tracking is not about micromanaging operators; rather, it is a strategic tool essential for gaining greater insight into the actual costs of manual activities. Precisely monitoring production not only helps identify inefficiencies but also improves resource utilisation, thereby optimising the entire production cycle. As a result, this leads to enhanced operational efficiency, which directly translates into increased revenue and a more sustainable, profitable production management.

-

Better staff management

-

Production process optimisation

-

Refining the OLE metric

-

Prevention of any critical points int the manual work phases

Opportunities arising from the survey of human time

Accurately understanding the time spent on processing parts is essential for correctly identifying and allocating resources across different production phases. Obtaining objective and concrete data on human time tracking and production quality is a key competitive advantage, not only internally but also crucially externally. For this reason, it is particularly important to explore how to effectively support business owners and decision-makers in optimising their industrial production processes.