From paper to digital: Efficiency for your warehouse

Your competitiveness starts right from the warehouse

Effective warehouse management is one of the most strategic factors in maintaining a company’s competitiveness.

That’s why a well-structured logistics flow, supported by advanced WMS systems, not only ensures accurate lead times, but also improves overall operational performance.

As a result, you can avoid stockouts, reduce unnecessary reorders, and keep warehouse saturation levels under control.

This leads to a more responsive and efficient supply chain, capable of adapting quickly to changes in demand.

-

Advanced algorithms for shelf and hold storage

-

Automatic operator missions generation

-

Stock movements from the beginning/end of the production line and picking

-

Both pre-set and configurable ERP integrations

Intralogistics useful for the production

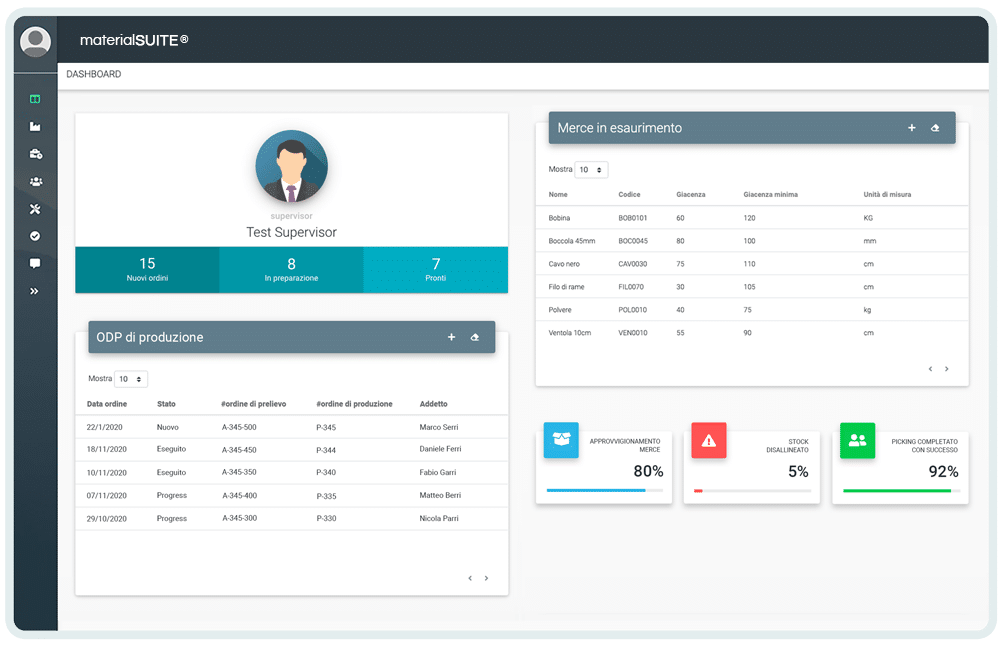

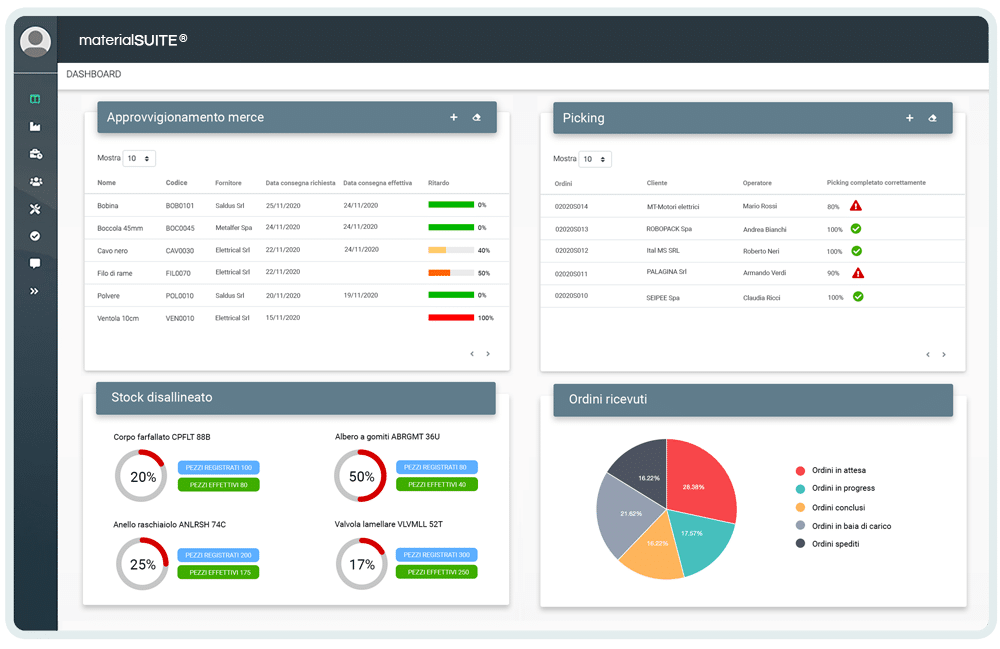

WMS system by materialSUITE® is an advanced solution for managing goods movement within both the production plant and the warehouse.

Indeed, the efficiency of intralogistics processes relies on accurate space mapping, clearly defined picking strategies, and constant monitoring of key performance indicators such as stock rotation and inventory levels.

As a result, using the system in a structured way helps prevent unnecessary reordering, reduce the risk of stockouts, and ensure smooth, ongoing communication between the warehouse and the production area.

In this way, WMS systems become a strategic ally generating value and profit through better internal flow management.

-

Interactivity between production and warehouse areas

-

Warehouse mapping configurable by the operator

-

Multi-warehouse and multi-site management

-

Storage rules that can be activated by the operator

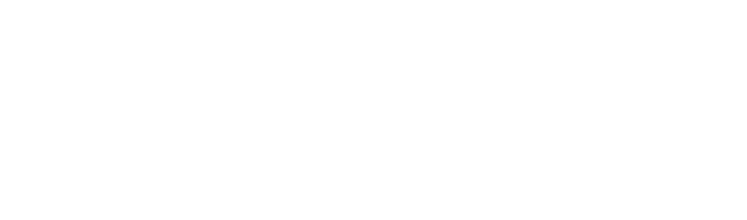

Stock monitoring and streamlined replenishment for a more responsive supply Chain

Effective planning of production activities and material resources is essential to optimise production times, capacity, and warehouse availability.

Therefore, to ensure a smooth flow, it is crucial to constantly monitor the stock turnover rate in order to accurately schedule replenishment timing and methods.

Moreover, WMS systems by materialSUITE® enable precise inventory management by keeping only the necessary quantities in stock and automatically triggering reorders once predefined thresholds are reached.

Thanks to advanced monitoring of logistics KPI, the WMS systems also helps optimise the entire supply chain, improving both costs and overall warehouse performance.

-

Fast identification of stock differences

-

Picking accuracy index

-

Supplier punctuality measurement

-

On-hand Inventory and average stay length for each reference

Custom solutions for smart warehouses

To successfully tackle the challenges of modern logistics, companies must first equip themselves with tools that ensure control, efficiency, and responsiveness.

The WMS systems by materialSUITE®, developed by Logikamente, enable the digitalisation of warehouse management, improving accuracy in goods handling and making every process smoother and continuously monitorable.

As a result, automating logistics operations allows for better space organisation, preventing unnecessary build-ups and reducing the risk of long-standing stock.

Moreover, by cutting down on manual tasks, companies can achieve leaner management, optimising available resources while containing operational costs.

Finally, thanks to its flexible design, the WMS systems easily adapts to changes in demand, seasonality, and operational peaks, ensuring continuity and efficiency across the entire supply chain.