Machine time recording

Automatically detect machine times and improve production efficiency with always-updated data.

Collect and analyze data from your machines

Minimize costs and reduce waste to streamline production

Identify productivity drops

Identify and manage actual technical processing times

Measures the consumption of resources used in the production process

Collect data on your production efficiency

The advantages of being Industry 4.0

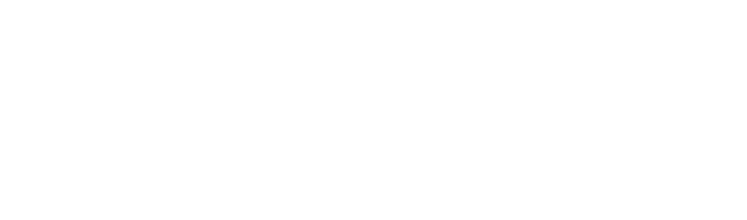

Machine time recording is a fundamental step in the effective control of production processes. In fact, knowing the actual working times makes it possible to accurately assess the OEE (Overall Equipment Effectiveness) of the plant. Furthermore, it makes it easy to identify bottlenecks, unplanned stoppages and interferences in production cycles. This information is essential to optimise the performance of the entire system. Thanks to machine time recording, real-time data can be collected from PLCs, sensors and on-board systems. Thus, you get a complete and constantly updated view of the operational status. The data is then processed in customisable, easy-to-read dashboards. As a result, it is easy to analyse each stage of production and take timely action.

In addition, this type of monitoring allows predictive maintenance to be activated. This reduces downtime and prevents sudden plant shutdowns. User interfaces must be intuitive and accessible. Indeed, it is essential that date, machine status and production phase are always available, even remotely. In conclusion, a machine time recording system improves operational efficiency. In addition, it provides reliable data to help make quick, evidence-based decisions. Implementing this technology is therefore a strategic step towards a more responsive, efficient and sustainable production model.

Link 4.0

Measure your production KPIs

Link 4.0

Machine time detection

Monitor and measure the status of your systems in real time by detecting KPIs