Bakery Ricchieri Millo sas represents the true passion of the master baker since 1968. Maintaining the flavours and knowledge of tradition also means marrying the concepts of Technology, Innovation and Industry 4.0. In fact, Panificio Ricchieri Millo, sas has invested in new technologies becoming the reference point of large food distribution.

Software MES release to optimise production progress

How production data helps you manage your business resources

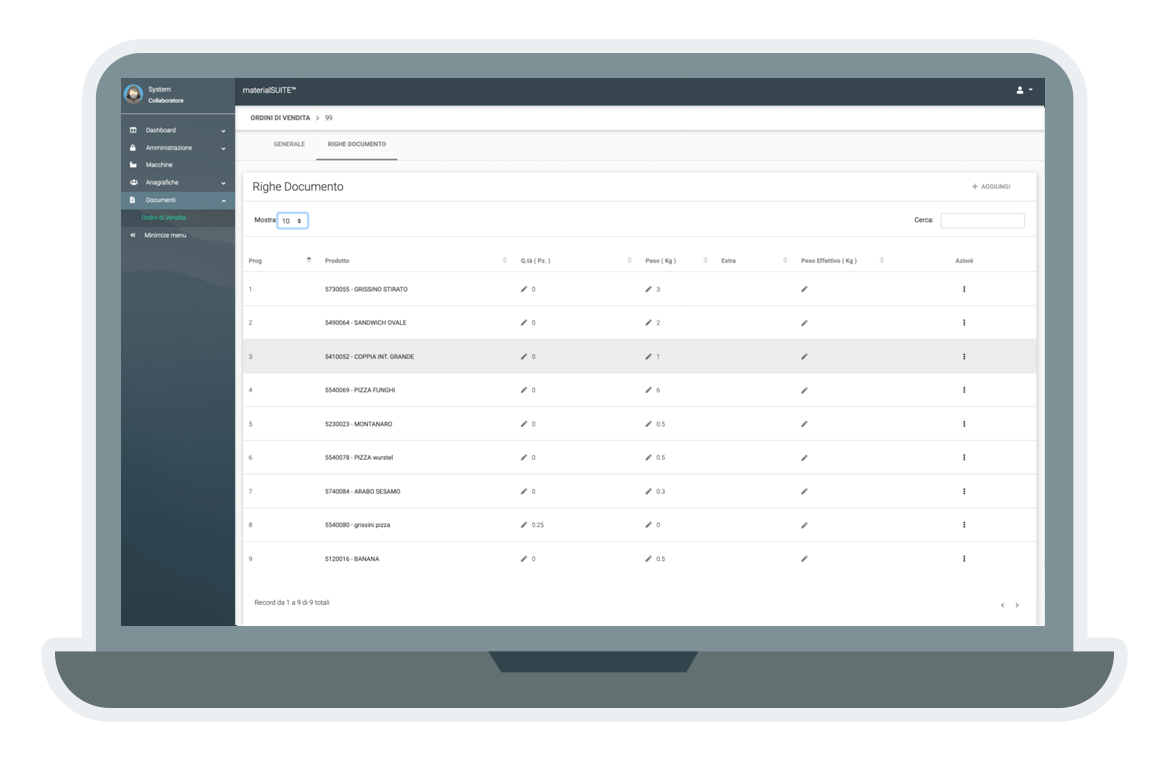

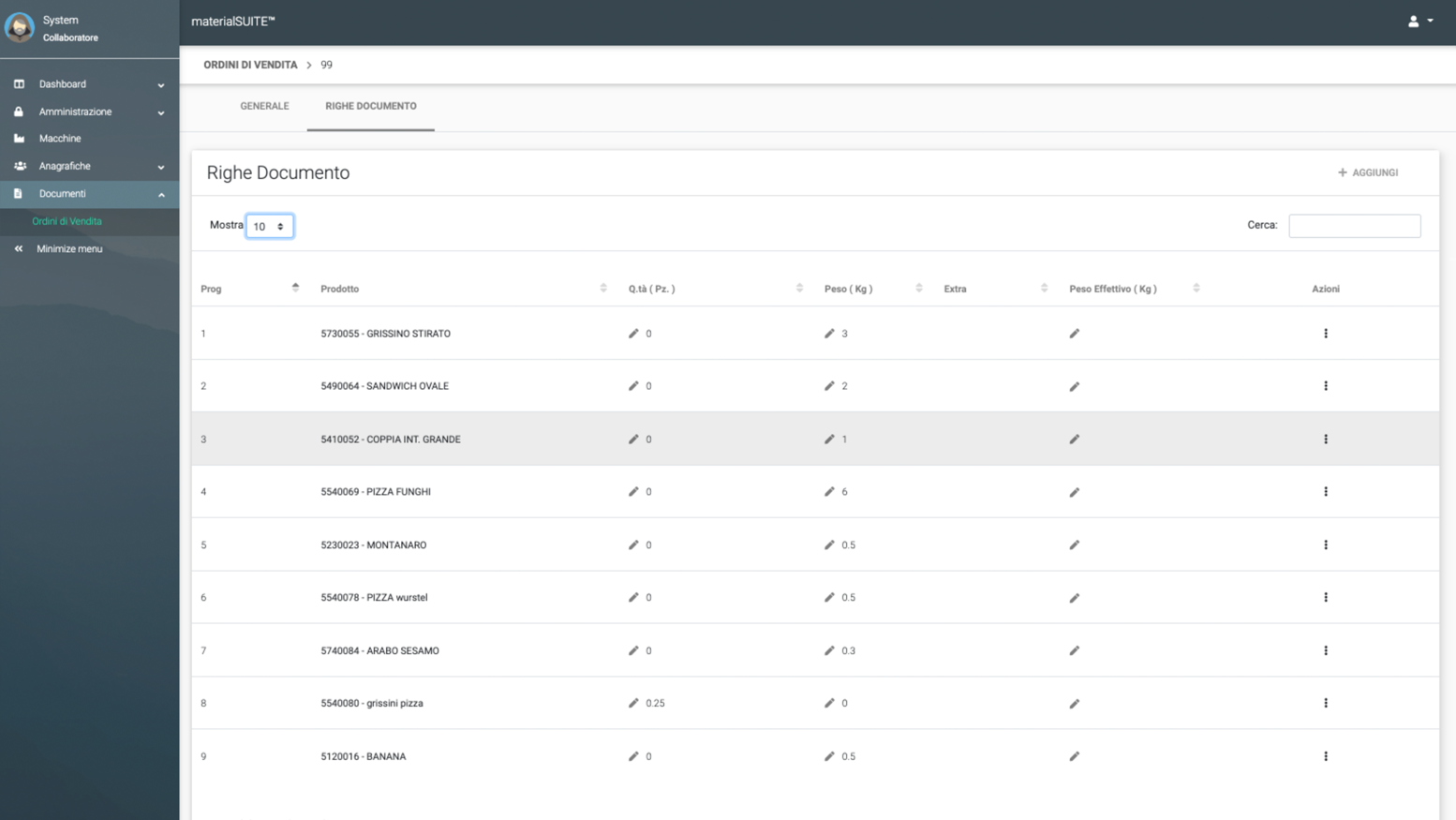

For the customer Panificio Ricchieri Millo sas has been developed a MES system with the aim of digitising the production and logistics of its bakery. The project has been developed on two main activities: the first consists in the machine data connection by digitising the orders coming daily from the customers. Each new order is placed inside the digitised system and then sent to the production department. The management of this process allows the administration to print the production orders and allocate the quantity actually produced and delivered to the customer in order to export the billing data within the Danea ERP.

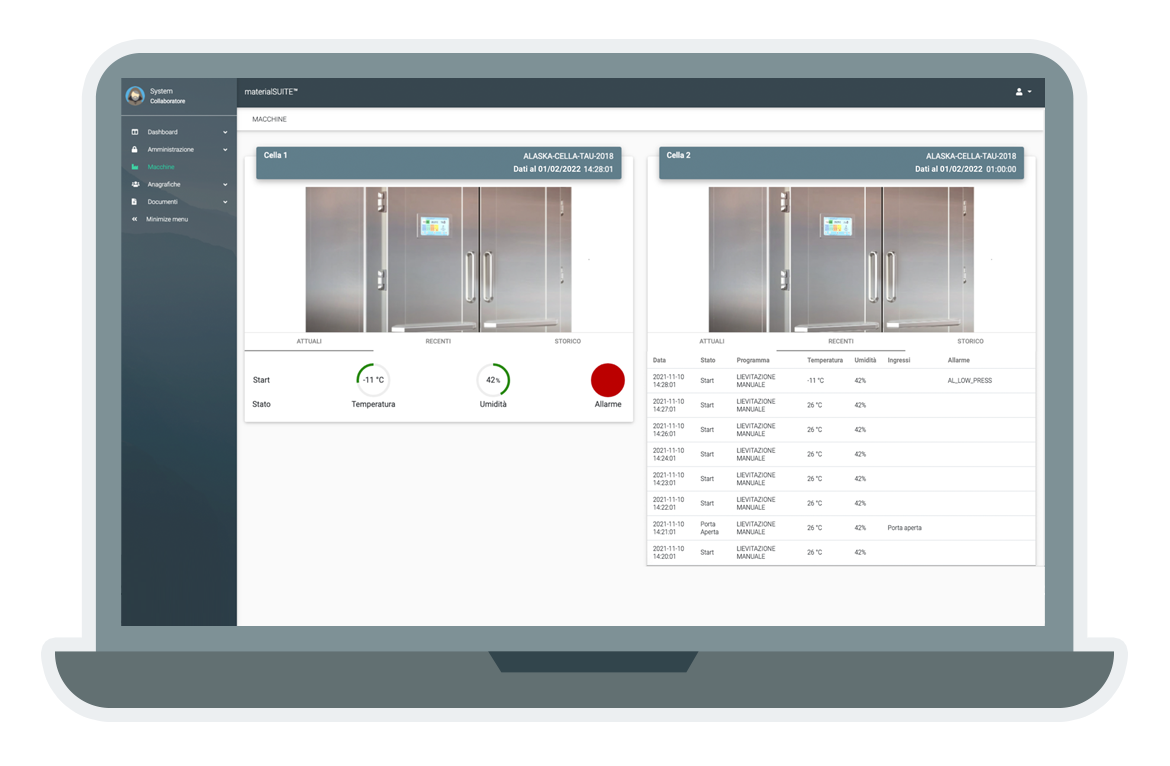

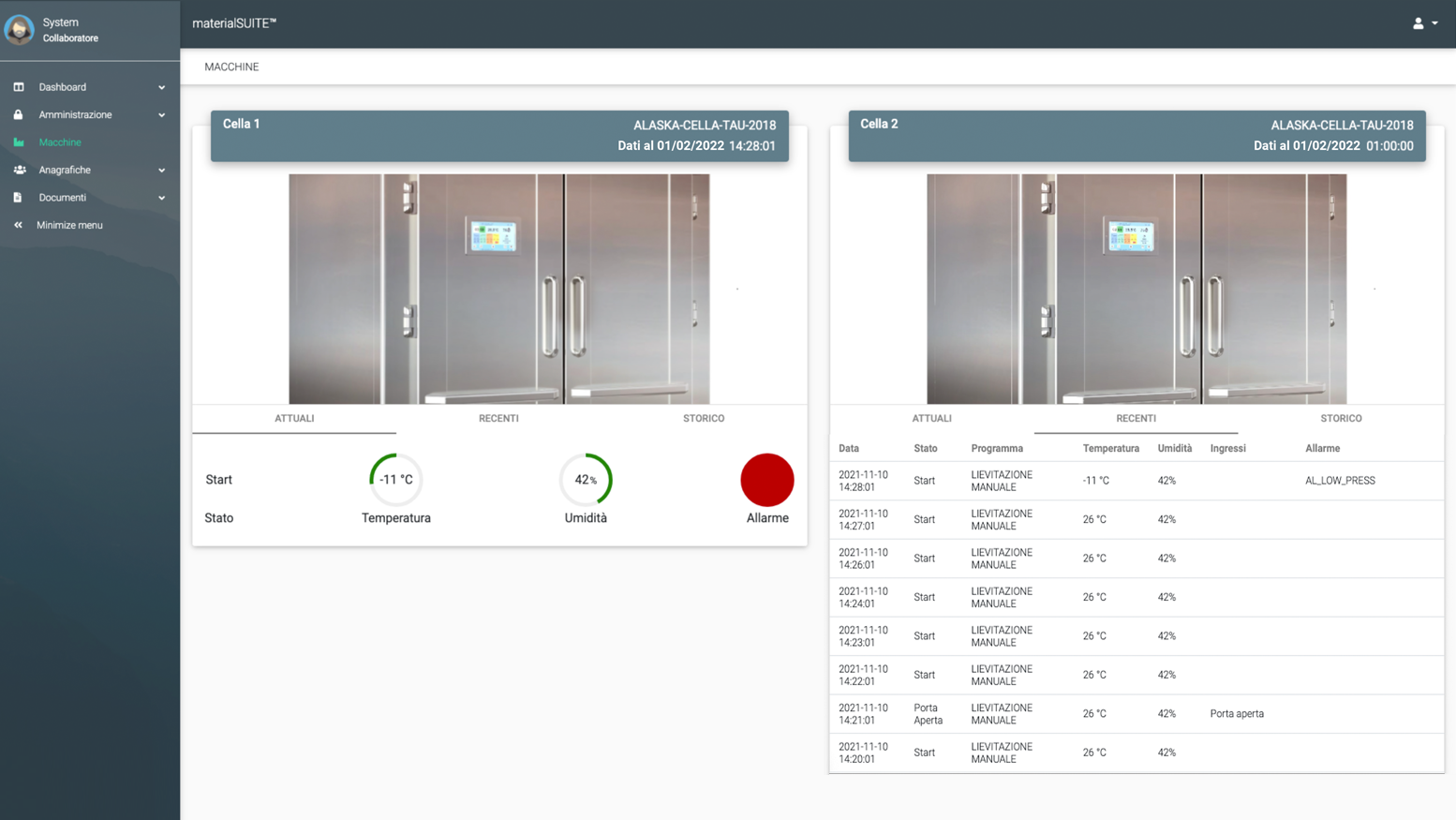

The second part of the project was carried out by connecting the proofing machines with the aim of exporting the statistical data of production progress and in particular the start and end of the leavening of the products.

Objectives

Digitise and speed up the management of paper orders and monitor the status of machinery

Solutions

Reduce the time allocated to the process of managing production orders and billing process, digitising much of the first manual and paper operations.

Benefits

The connection of the machines allows the customer to monitor them, for example, by knowing the stage in progress, the program started, the operating parameters and the progress of production. This data enables the customer, as well as decision makers, to support personnel choices based on actual production insights.

Integrations