Bidirectional interconnection for Industry 4.0 machines

4.0 Connectivity with materialBOX® for the Fenix sorting machine

Ferri Luigi Sementi Srl, a seed company operating since 1950, is a recognized Italian leader in seed selection. Thanks to a strong distribution network, the company exports extensively across Europe.

4.0 Machine connectivity with materialBOX® for advanced production control

Optimize production with bidirectional data flow between machines and KPI software

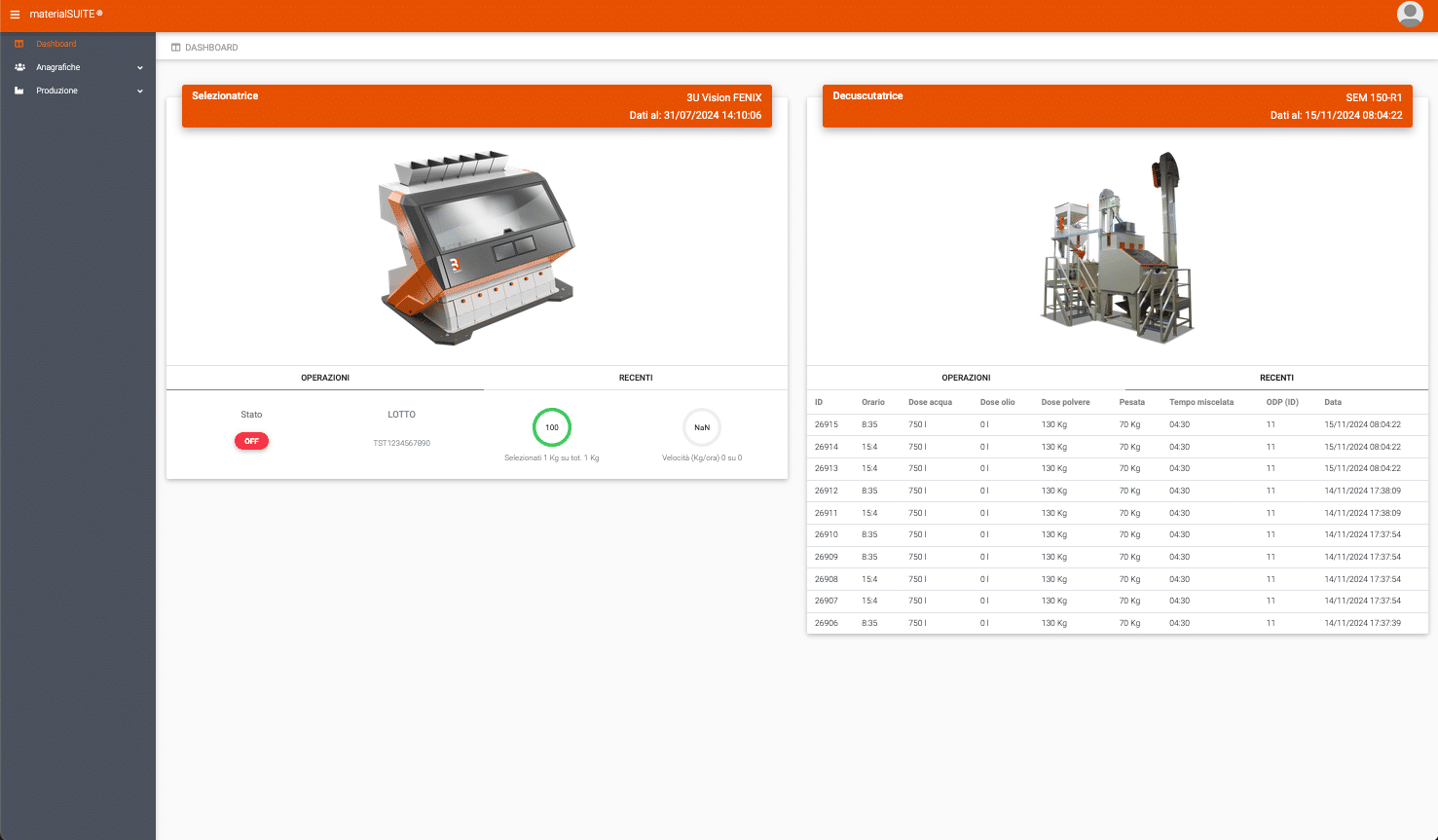

Ferri Luigi Sementi needed to integrate its Industry 4.0 machine – the Fenix 3U Vision sorter – with an advanced KPI Software solution to improve production data monitoring and streamline order management.

By implementing materialBOX®, the company can now collect and analyze machine-generated data for each production order, gaining full visibility of resource usage and performance. The workflow has been completely automated:

- Manual entry of the production order

- Recipe transfer directly to the Fenix sorter

- Product selection according to configured parameters

- Real-time collection of production data

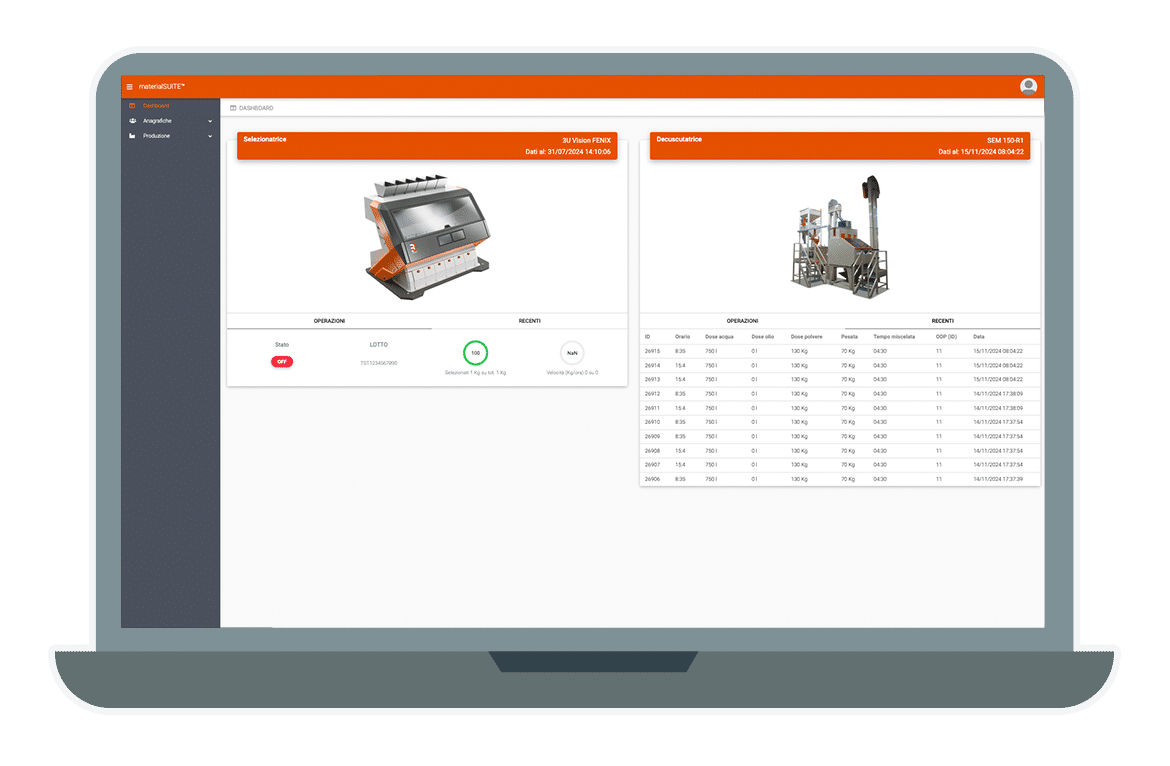

- Visualization of orders and performance via dashboard

With this system, Ferri Luigi Sementi can monitor machine status, last executed order, and selected vs. rejected product weights, ensuring maximum efficiency and accuracy.

Objectives

Create a system capable of bidirectional interconnection with the Fenix 3U Vision sorter to optimize processes and monitor production KPIs in real time.

Solutions

mplementation of materialBOX®, the industrial connectivity and KPI Software that enables seamless integration between Industry 4.0 machines and the company’s ERP system.

Benefits

* Full integration of machines and business systems, real-time KPI tracking and production monitoring, increased operational efficiency and reduced manual errors, data-driven planning and complete process traceability

Integrations