Tommasin & C. S.r.l., is an Italian company specialised in metal contractions, specifically dished bases; has adhered to the incentives provided for the 4.0 Industry with the aim of optimising production processes using software capable of speeding up numerous activities, previously managed by incorrectly computerised supports. The company, which today has important growth goals and aspirations, can count on highly qualified personnel and important certifications including ASME Pressure Vessel Manufacturing.

Reduce Energy Consumption

Gain Energy Awareness

Tommasin Srl partnered with us to develop its first Transition 5.0 project, aiming to optimize the energy efficiency of its industrial extraction system while improving safety across the production plant.

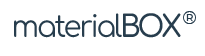

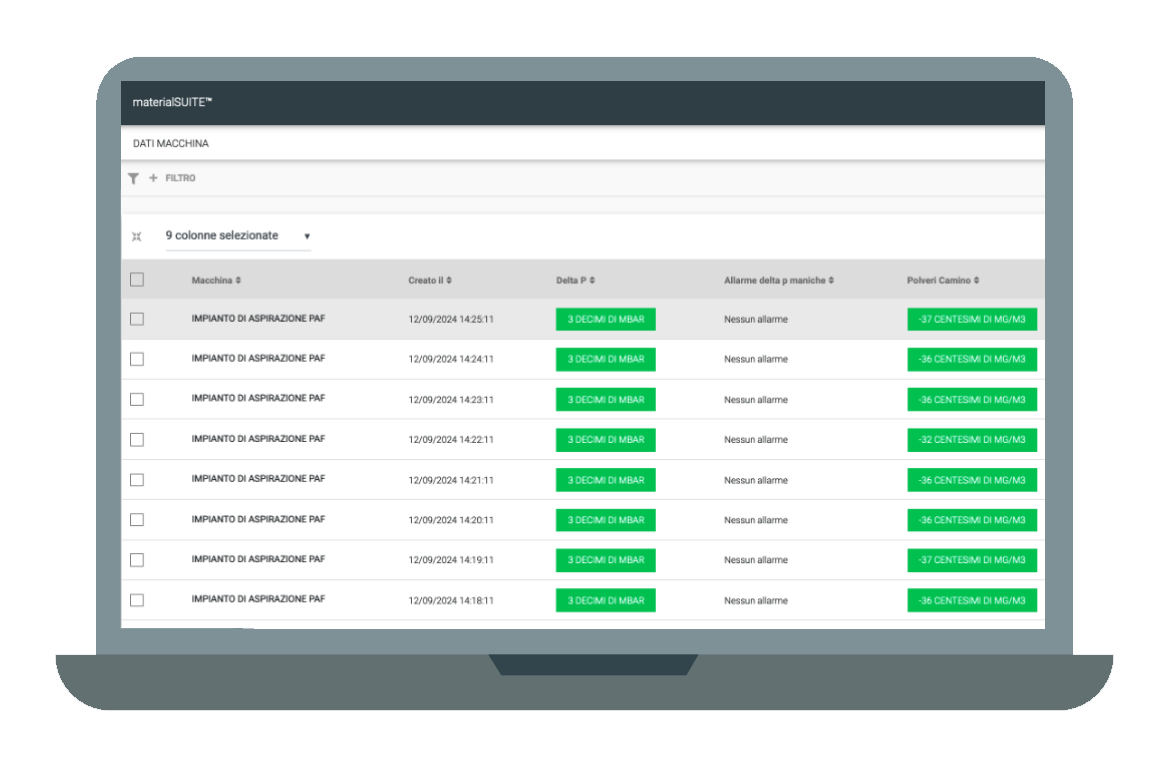

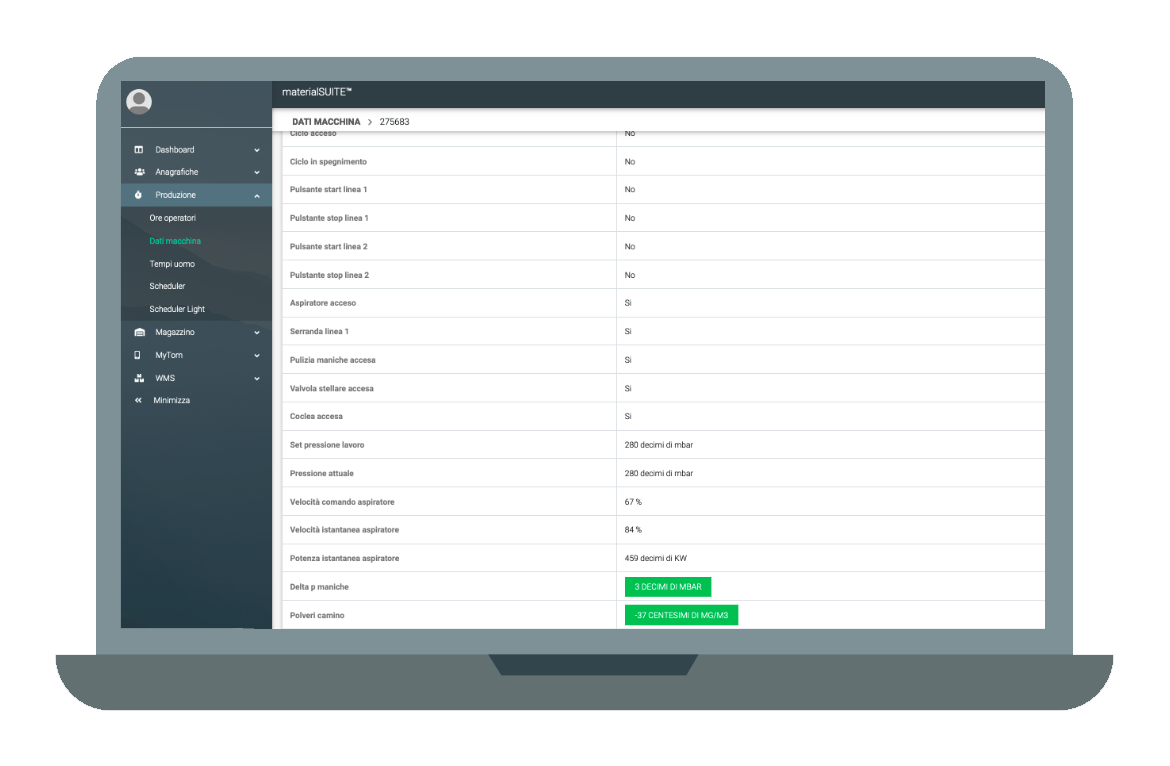

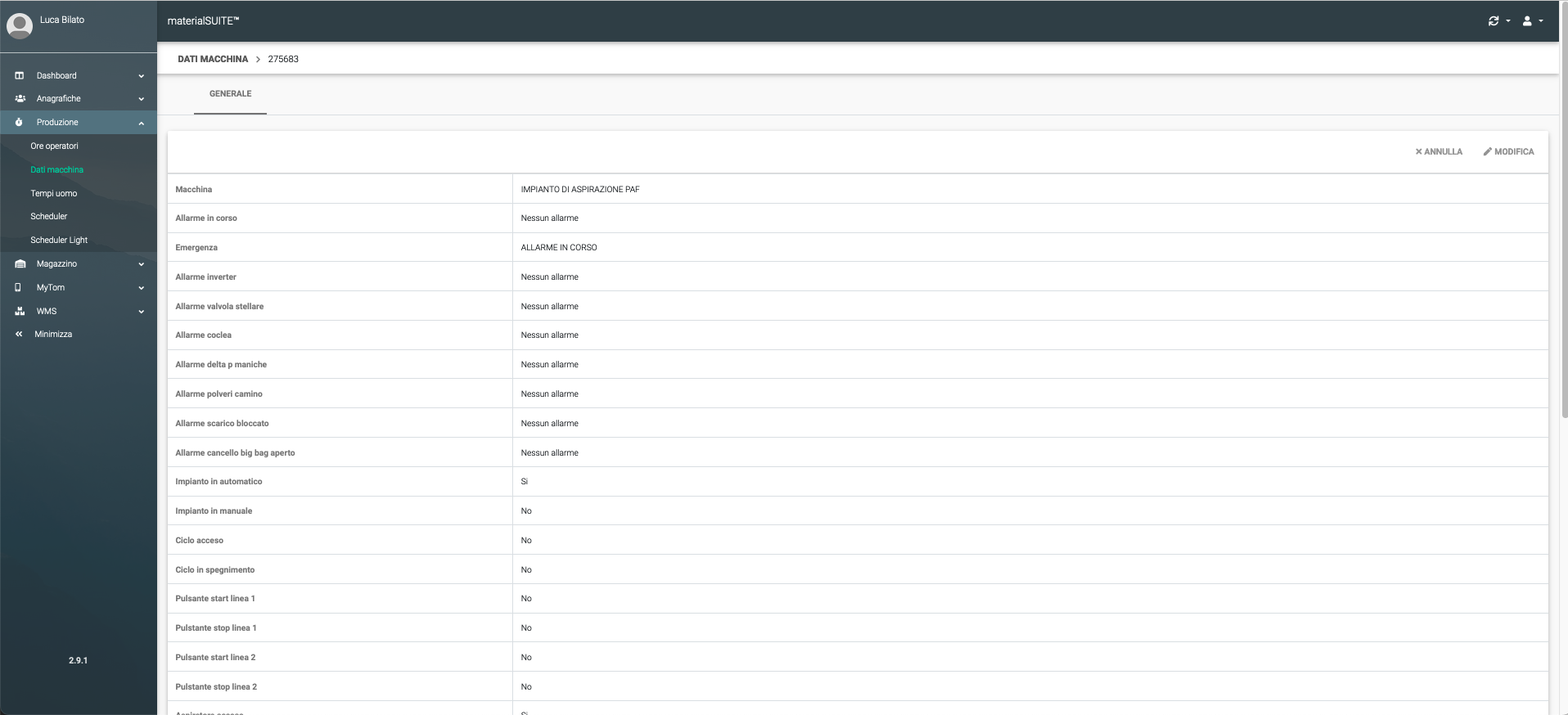

Through the installation of our materialBOX® integrated with materialSUITE®, the company can now monitor in real time:

- Energy consumption status

- Self-produced and self-consumed energy

By integrating advanced sensors and IoT field devices, the system continuously collects and processes data, presenting it clearly and accessibly through dedicated energy dashboards.

Thanks to our advanced software solution, Tommasin Srl can:

- Optimize energy consumption

- Manage self-produced energy efficiently

- Generate periodic energy reports

- Monitor real-time energy usage

- Analyze key energy KPIs

With the integration of materialSUITE®, technical and operational staff have quick access to all critical information, ensuring better safety and energy awareness within the production plant.

Objectives

Improve the energy efficiency of the extraction system

Solutions

Installation of a continuous energy monitoring software

Benefits

Greater safety in the production plant and increased awareness and control of energy usage

Integrations