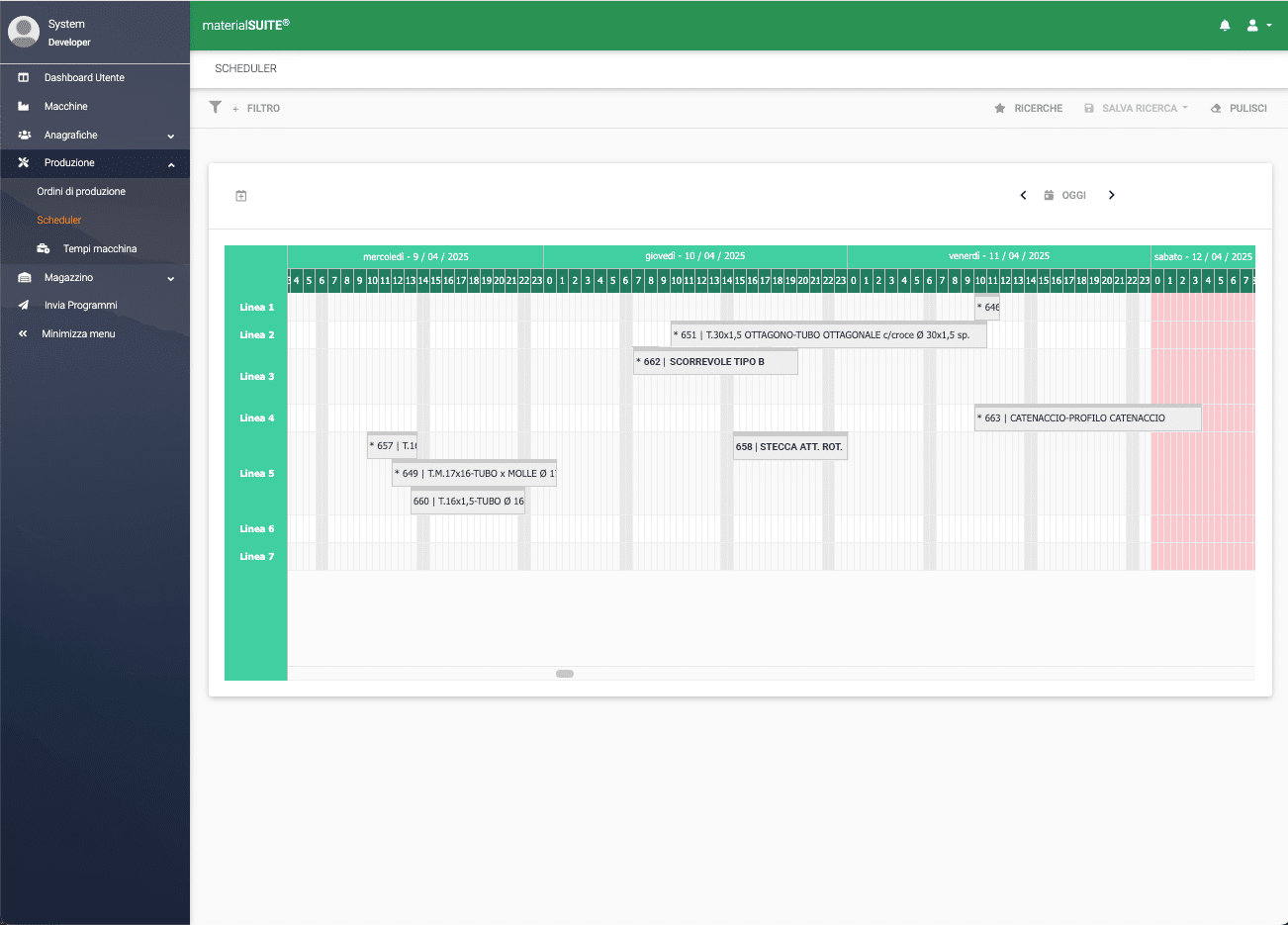

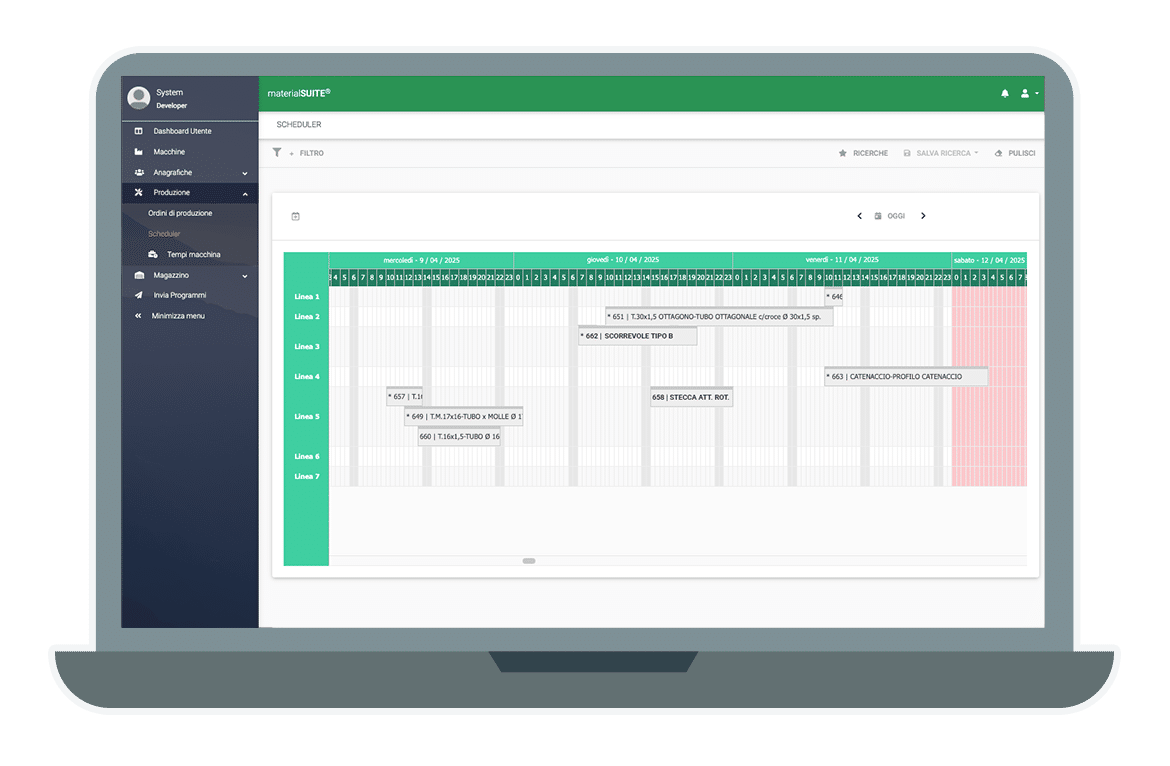

Smart Production Scheduling with the SCH Module

Optimizing production scheduling for a more agile and efficient workflow

Since 1977, Profilplast di Ramadani Cesare & C. snc has specialized in the customized production of extrusion equipment for plastic materials, as well as the manufacturing of molds, dies, calibrators, rigid and semi-rigid PVC profiles, and agricultural products. Leveraging decades of experience, the company delivers highly precise, tailor-made solutions in record time.

Agile, Accurate, and Aligned Process Planning

SCH Module integrated with production and logistics

Optimizing Process Scheduling for Maximum Efficiency

For Profilplast, a company specializing in plastic material processing, the main challenge was improving intralogistics flow management and optimizing production bill-of-materials scheduling. By implementing a customized SCH module, it became possible to introduce dynamic and flexible process scheduling, ensuring accurate planning aligned with available resources and delivery deadlines.

Adopted Solution

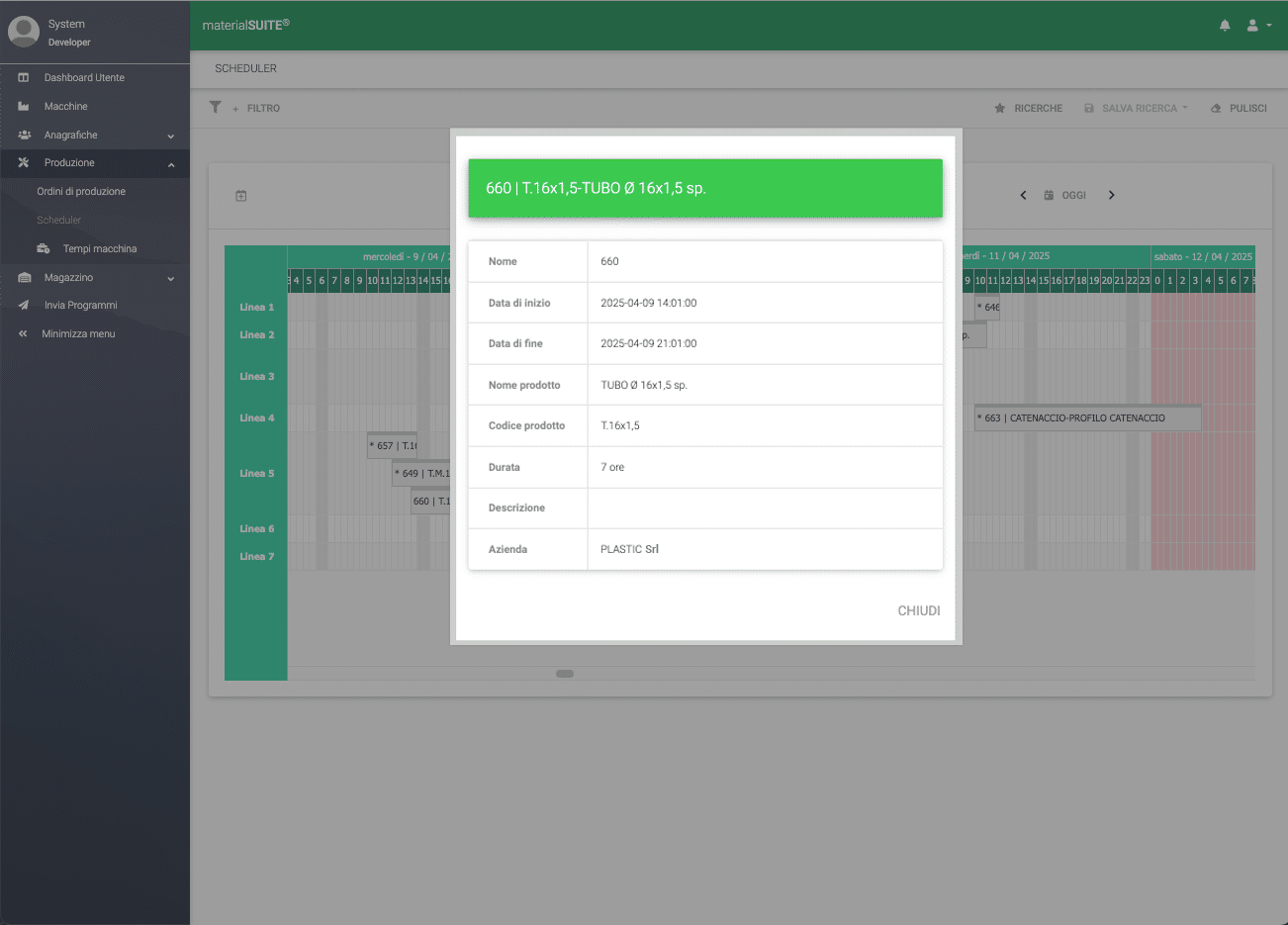

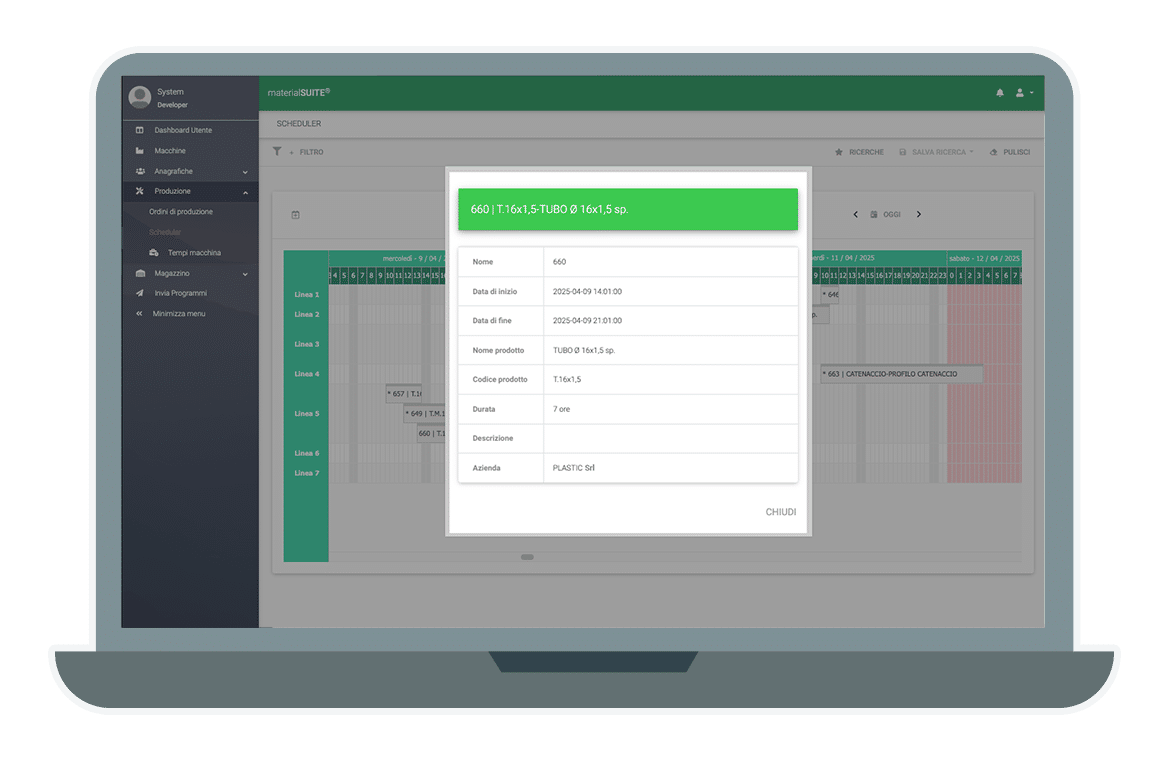

We developed a custom version of the SCH module, integrated into materialSUITE®, enabling precise production scheduling based on work completion dates and resource availability. The system automatically adapts to changes, making planning more reliable and streamlining the workflow between production and warehouse operations.

Key Benefits Achieved

- Optimization of production bill scheduling, reducing planning time

- Better utilization of resources and machinery with a complete view of activities

- Ability to plan based on real deadlines, improving on-time delivery performance

- Reduced lead time and increased overall productivity

- Greater operational flexibility, with immediate recalculation in case of changes

- Intuitive interface with drag & drop functionality for quick and easy management

Thanks to production scheduling with the SCH module, Profilplast now manages its production more efficiently, minimizing delays and enhancing responsiveness to market demands.

Objectives

Improve intralogistics flow management and production bill scheduling, achieve more agile and accurate process planning aligned with resources and deadlines, and increase overall efficiency by reducing delays and lead time.

Solutions

Implementation of a customized SCH module integrated into materialSUITE®, enabling dynamic and flexible production scheduling software. The system considers completion dates and resource availability and adapts automatically to changes, supported by an intuitive drag & drop interface.

Benefits

Reduced planning time and improved overall productivity. Better resource and machinery utilization thanks to a complete view of activities, increased operational flexibility, and improved on-time delivery performance with fewer delays.

Integrations