Intralogistics workflows, from Delivery Note to production

Management of RFQ, goods receipt, and warehouse mapping

Keytek Srl was founded in 2002 in Formigine (MO). Driven by a passion for graphics and digital printing, the company has grown in the market by consistently delivering high-quality products with an innovative vision. Today, Keytek produces ceramic merchandising, graphic displays, durable stands, and decorative panels, supported by full production digitization and over 20 years of experience.

To optimize intralogistics management, Keytek Srl chose to digitalize warehouse operations with a customized Warehouse Management System (WMS) tailored to their specific needs.

The primary goal was to improve operational flow efficiency from goods arrival to the production phase. Since Keytek works on a contract manufacturing basis, each incoming shipment is linked to a specific production order.

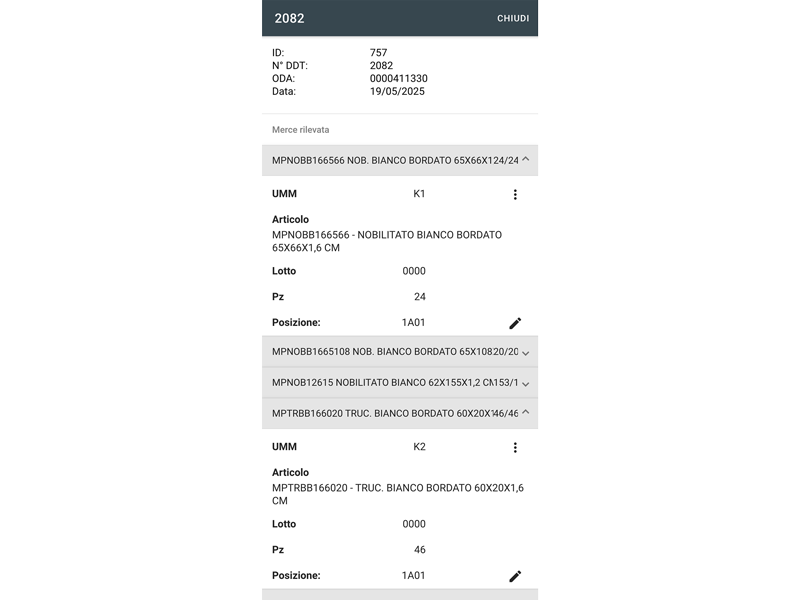

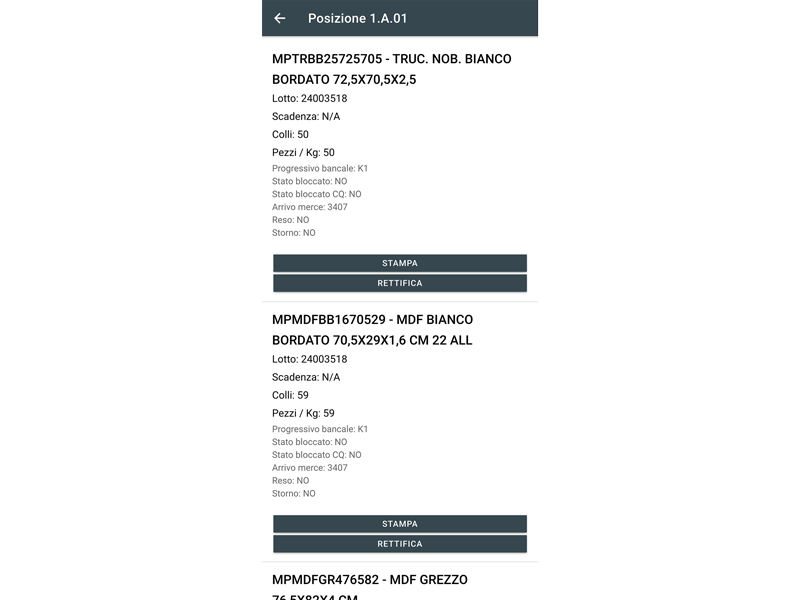

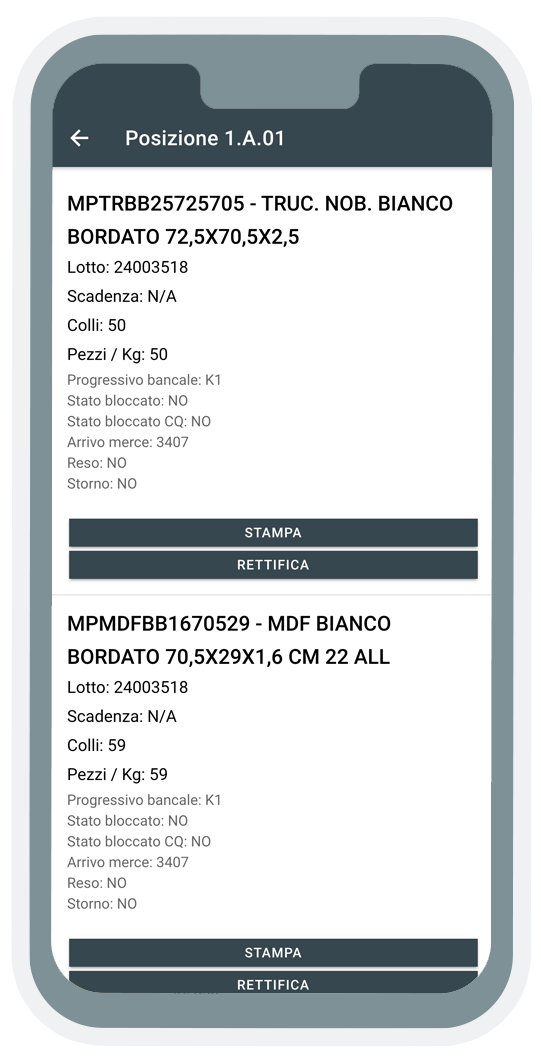

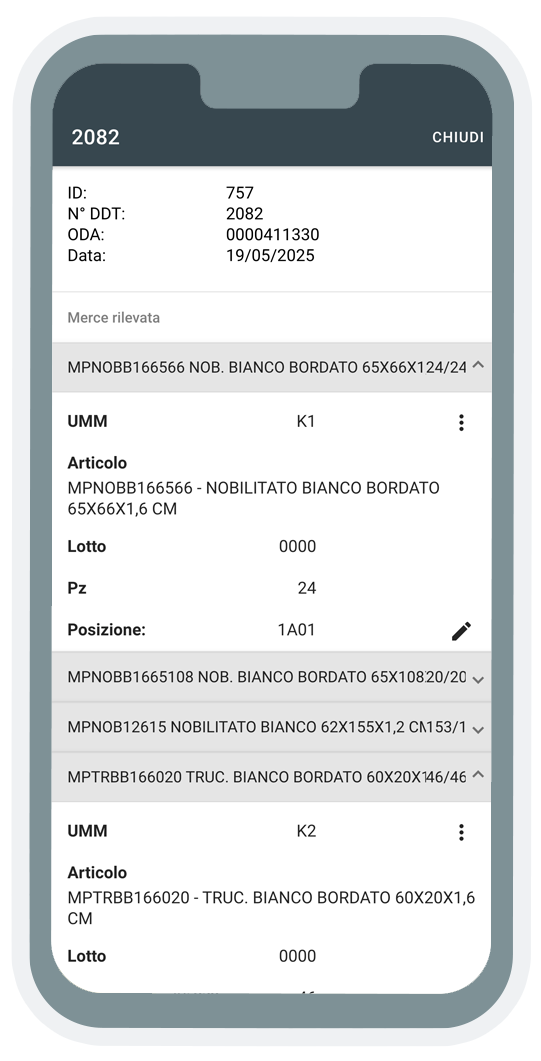

Thanks to the integration of our WMS with the Ad Hoc Infinity ERP system, the software automatically records goods receipt upon Delivery Note (DN) arrival, enabling structured pallet management. Pallets are placed in predefined warehouse locations, mapped with QR code labels for full traceability.

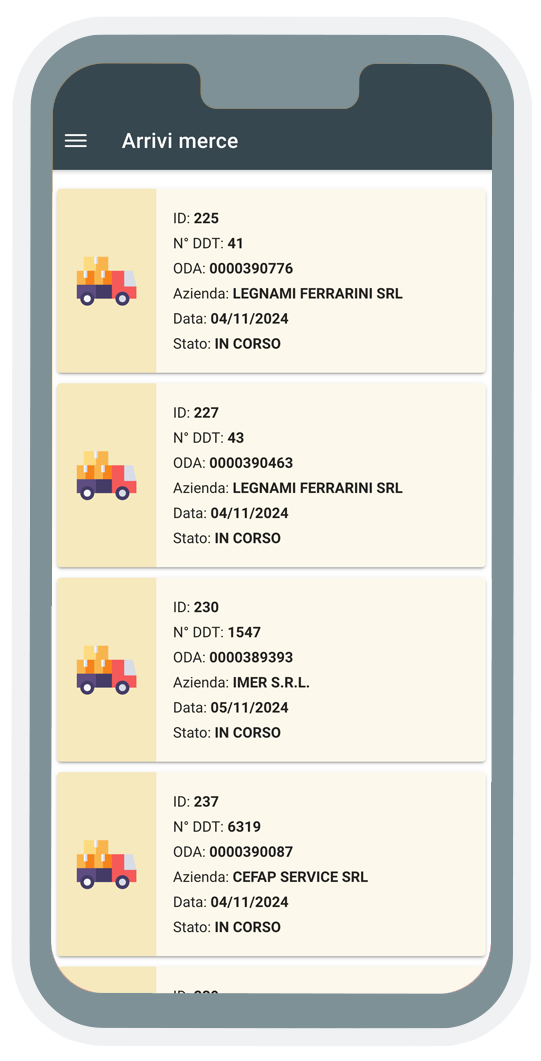

Using the WMS mobile app, warehouse managers can handle all movements in real time, ensuring constant control over stock levels and their precise locations.

Now, thanks to materialSUITE® , with its WMS module the technical and operational staff can:

- Manage Supplier Orders linked to Goods Receipt

- Have complete visibility of warehouse inventory levels

- Automate goods receipts

- Guarantee stock traceability

- Handle all warehouse stock movements

With the integration between materialSUITE® and the Ad Hoc Infinity ERP, personnel have easy access to all production-related information, significantly improving communication across all company departments.

Objectives

A unified and accessible software system to optimize delivery times

Solutions

Installation of materialSUITE® software with MES, WMS, and MTM (Time and Methods) modules

Benefits

Full visibility of production stages and timings, leading to greater efficiency in delivery times

Integrations