Our Areas of Expertise

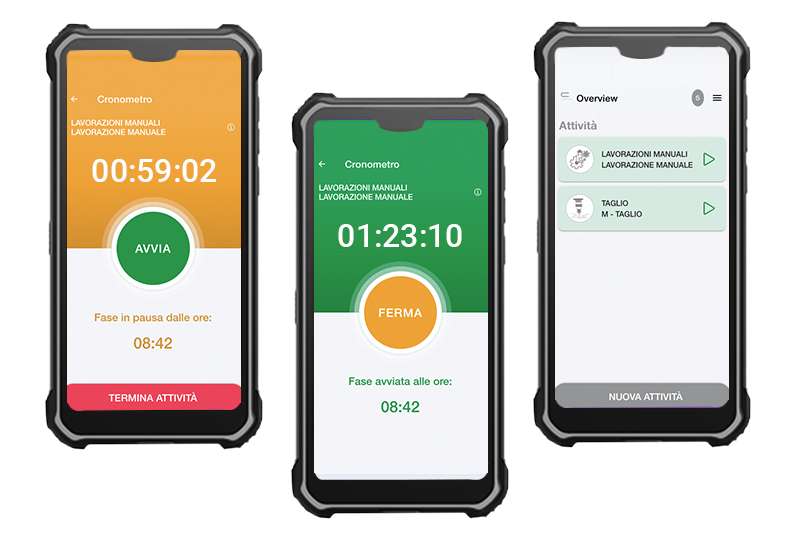

Labor time tracking

Collect and monitor production times generated by your operators to improve work quality.

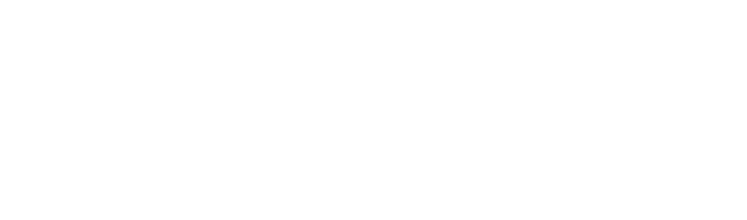

Machine Connectivity 4.0

Monitor and measure the real-time status of plants through KPI tracking.

Employee attendance and visitor tracking.

Track employee attendance and monitor visitor access.

We integrate any

ERP software

Optimizing production has never been easier

Our software solutions are, in fact, simple, intuitive, and customizable, designed to manage production with a focus on User Experience. First, we carefully listen to your needs, then we identify your priorities, and finally, we tailor the software, creating a unique solution aimed at optimizing the management of your production. In this way, we ensure a product that perfectly meets the specific needs of your business.

Production progress and traceability

Monitor in real-time the progress of orders, facilitating the order completion process within the expected timeframe.

Easy and Fast Production Input

During production input, operators can quickly assign the status of "semi-finished" or "finished product" to the completed work.

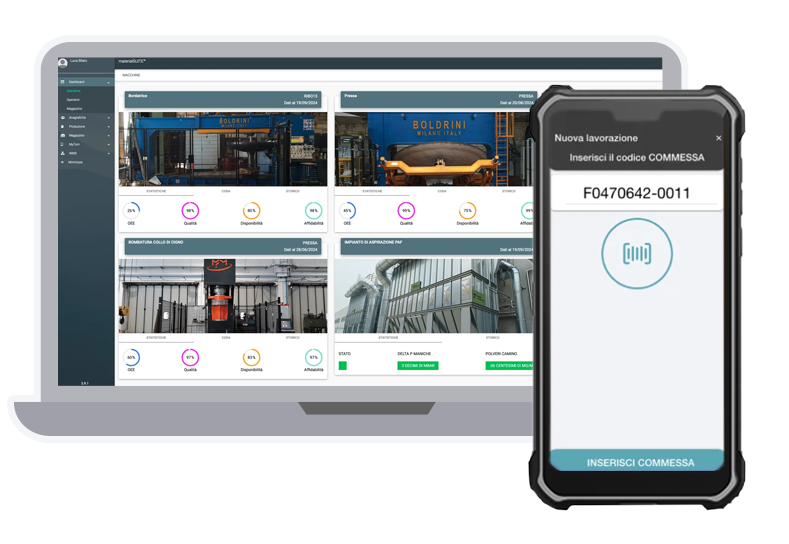

Greater Efficiency in Goods Flow Management

Get real-time updated data on the availability of necessary resources in the warehouse for order completion.

Better communication between the production plant and offices

Fill the communication gap between offices and the production plant through the integration of MES software with other existing business management systems.

Optimized Stock Management

Defining your warehouse’s stock-out threshold allows you to monitor product availability in real-time, avoiding unnecessary orders and the risk of running out of stock.

Goods Movement In and Out

Monitoring inbound and outbound movements from the warehouse ensures precise stock control and optimal flow management.

Monitor the Turnover Rate

Analyzing the turnover rate is essential for optimizing procurement times and methods, ensuring the availability of necessary goods without excess stock.

Automatic Refill Mission Generation

Through the WMS software, you can automatically generate operations to replenish storage areas, optimizing procurement times and eliminating manual errors.

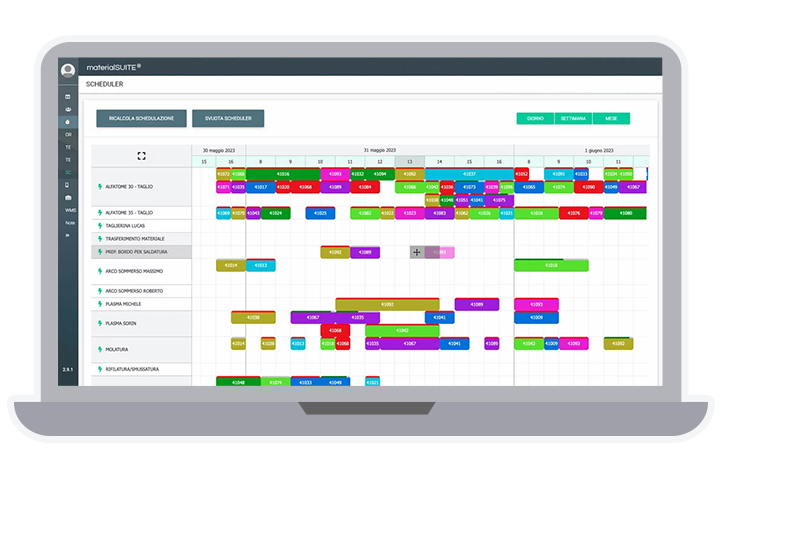

Accurate Delivery Date Estimation

The production scheduler allows you to develop production plans considering order priorities, deadlines, and labor availability, ensuring on-time deliveries.

Operational Plan Formulation

Scheduling enables you to plan the start of production based on inventory procurement, synchronized with the WMS software.

Production Sequence Simulation

With the SCH software, you can create a detailed representation of the production process for an order, anticipating potential issues and reducing downtime.

Increase in Production Efficiency

Production scheduling allows you to define the timing of production stages, advancing or suspending processing steps to meet lead time requirements.

Precise Definition of Production Costs

Knowing the production times and methods of your operators is essential, especially for companies with manual production stages.

OLE Metric Tracking

This KPI allows decision-makers to determine the impact of labor on production performance.

Identifying Causes of Production Inefficiencies

With the MTM software, inefficiencies caused by unnecessary movements, prolonged waiting times, and inefficient processes can be detected, allowing for targeted solutions to optimize operations.

Quantifying and Forecasting Workforce Performance

This process involves analyzing cycle times, productivity per unit of time, work quality, and resource utilization levels, thus improving overall production capacity.

Who believed in us

FAQ

Logikamente is an Italian software house specialising in customised software solutions for optimising production processes in the manufacturing industry. We offer four main solutions: materialSUITE® for production and warehouse management (MES, WMS, SCH, MTM), materialBOX® for Industry 4.0 machine monitoring and OEE calculation, fluxHR® for attendance tracking and HR management, and donia® the AI agent for industry. All our solutions integrate with leading ERPs such as SAP, Microsoft Dynamics NAV, IBM, Passpartout, Sistemi, Team System, Zucchetti, Oracle and many others.

The cost depends on several factors: company size, number of users, modules required and process complexity. For simple projects, the timeframe is 2-3 months, while for more complex solutions it can be up to 6-12 months. We offer software solutions that can be installed either in the cloud or on-premise. Contact us for a personalised quote based on your specific needs.

materialSUITE® natively integrates with the main ERP systems on the Italian market: SAP, Microsoft Dynamics NAV, IBM, Passpartout, Sistemi, Team System, Zucchetti, Oracle and many others. Integration takes place via APIs and specific connectors that guarantee real-time bidirectional data exchange, synchronising production orders, warehouse movements, bills of materials and product master data without duplication.

Logikamente stands out for three main reasons: complete customisation of solutions to the specific needs of each manufacturing company, concrete support throughout the digital transition and consolidated experience in the plastics, assembly, food, metallurgy and chemical sectors with over 100 successful implementations. In addition, our solutions are already Industry 4.0 certified and compatible with tax credits.

The first tangible results can be seen within 2-3 months of operational start-up. On average, client companies report: a 20-30% reduction in warehouse management times, a 15-25% increase in production efficiency through optimised scheduling, a 30-40% reduction in manual errors, and a 25% improvement in delivery estimate accuracy. Full ROI is typically achieved within 12-18 months.

Yes, we offer free 60-90 minute customised demos where we showcase features specific to your industry and processes. Upon request, you can activate a 30-day pilot trial with real data on a limited department to evaluate the benefits and usability before making a full investment. Book your demo on our website.