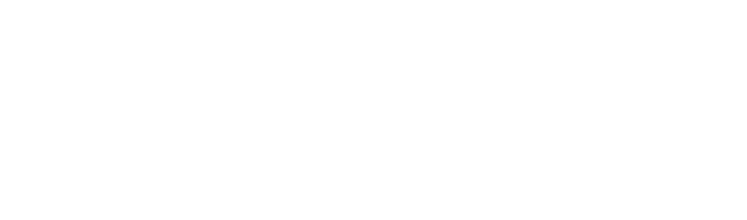

Production management and Warehouse monitoring

Monitor progress and optimize storage flows for enhanced production management

Real-Time Efficiency and Control

Production Progress and Traceability

Fast and easy production reporting

Automatic refill mission management

Increased efficiency in goods flow management

Reduction of bottlenecks

Synergy between MES and WMS

Optimized production control is essential to ensure efficiency and competitiveness. The integration between MES (Manufacturing Execution System) and WMS (Warehouse Management System) represents a crucial synergy for improving intralogistics operations. MES allows real-time monitoring of production status, ensuring that resources are used optimally and cycle times are reduced. At the same time, WMS manages warehouse activities, from receiving raw materials to shipping finished products, ensuring accurate inventory management and minimizing errors. Implementing these modules provides complete visibility of the production and warehouse flow, improving planning, reducing downtime, and optimizing resources. Effective production management, integrating MES and WMS, leads to more agile logistics and full process control, increasing profitability.

MES and WMS

to optimize intralogistic flows

MES

Progress and Traceability

Plan production, monitor progress, collect real-time production data, and make processes more efficient in your factory.

WMS

Warehouse Management

The WMS software to control, coordinate, and optimize storage flows within a production plant, interacting with other production management systems.