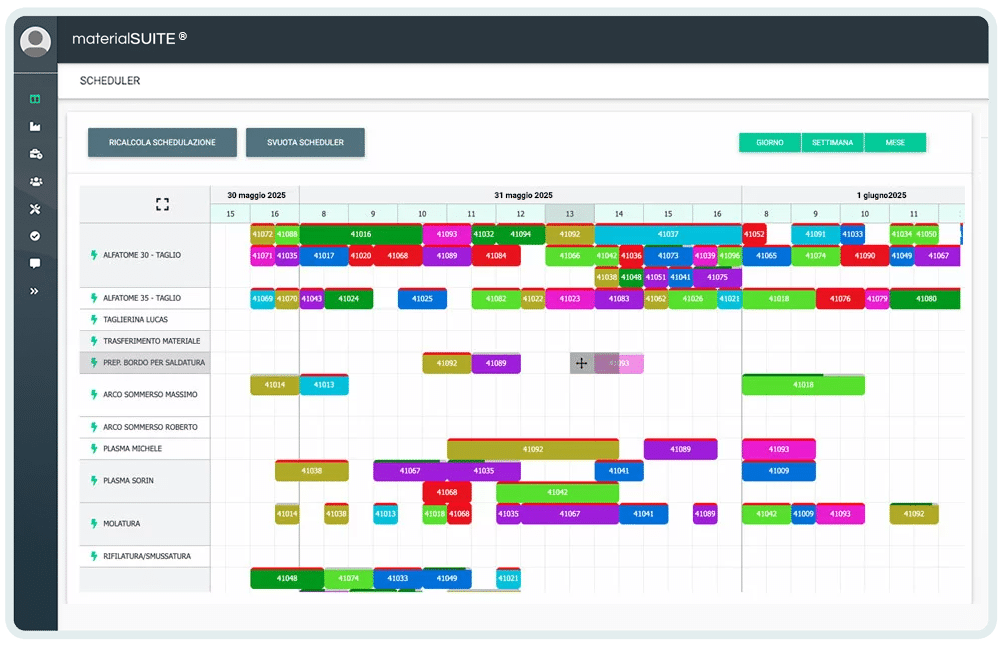

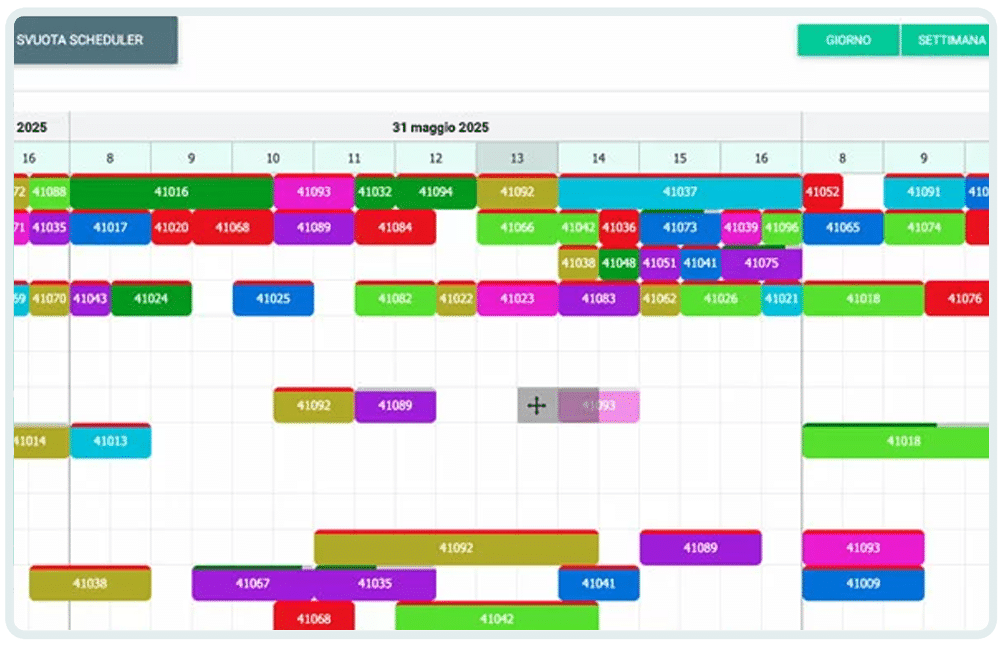

Optimize production planning with scheduler software

Manage production efficiently, reducing waste

Production scheduling involves precisely and dynamically defining the timing of operational phases with the goal of maximizing the efficiency of the production process.

By using the materialSUITE® production scheduler software, it is possible to plan and sequence orders while taking into account both the availability of internal resources such as labor and machinery, and the status of supplies and inventory levels.

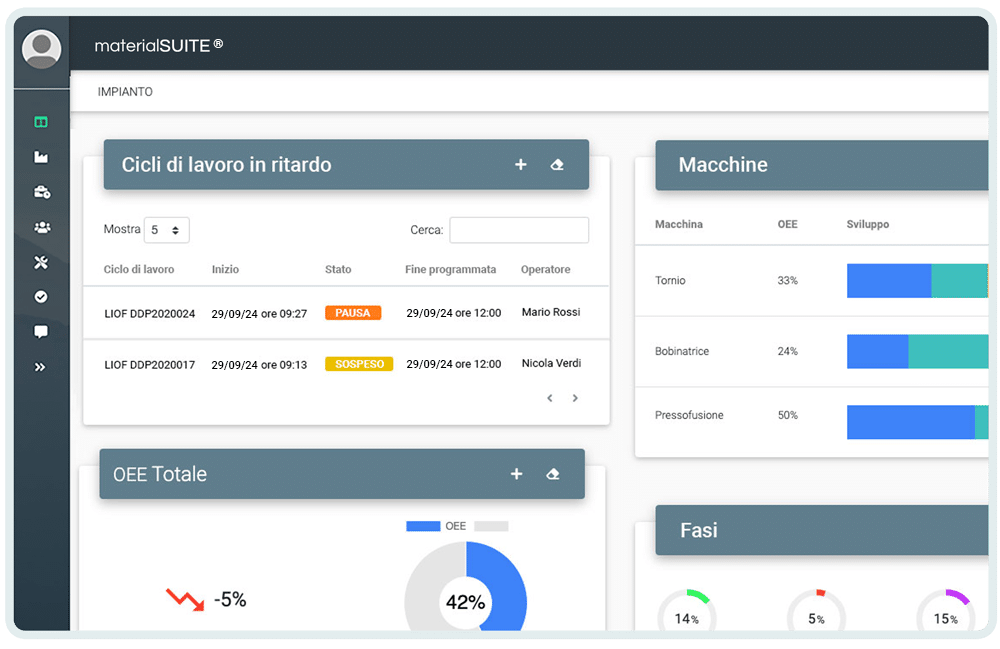

Furthermore, thanks to integration with MES and WMS software, the scheduler software provides a real-time view of the entire production process.

As a result, it becomes possible to automatically and responsively determine the optimal sequence of activities, reducing downtime and ensuring lead times are met. This approach allows for the creation of a coherent production plan that is truly aligned with the needs of the supply chain.

-

Formulation of the operational plan and push production plan

-

Gradual elimination of paper

-

Production sequence simulation

-

Real time view of what is happening on the shop floor

Plan production with scheduler software tailored to your business

The materialSUITE® production scheduler software uses heuristic algorithms and flexibly adapts to the specific processes of each company by applying three scheduling models based on operational needs:

- Finite capacity scheduling: focuses on the balanced distribution of activities across lines, departments, or operational resources, with the goal of optimizing the production cycle, reducing bottlenecks, and ensuring efficient utilization of available capacity.

- Reverse scheduling: plans backward from the customer delivery date, calculating the necessary time for each phase to guarantee deadlines are met while optimizing early starts and stock levels

Thanks to these models, the production scheduler software enables the development of customized work plans that consider order priorities, deadlines, setup times, labor availability, and the specific characteristics of each production plant.

-

Required planner effort reduction

-

More time for your valuable activities

-

Continuously updated planning, accessible to all team members

-

Precise estimate of delivery dates

Why rely on production scheduler software: advantages and benefits

Adopting production scheduler software allows you to optimize resource utilization by significantly reducing downtime and bottlenecks that often slow down the production flow. Additionally, it improves planning accuracy, ensuring strict adherence to delivery dates and, consequently, increasing end-customer satisfaction.

Thanks to dynamic and flexible planning, the scheduler software facilitates timely management of changes and unforeseen events, enabling rapid adjustment of work schedules. At the same time, it helps minimize inventory and work-in-progress, thereby reducing warehouse costs and tied-up capital.

Overall, implementing production scheduler software enhances operational efficiency, improves decision-making capabilities, and strengthens the company’s competitiveness in an increasingly demanding market.

-

Production costs reduction

-

Icreased production efficiency

-

Optimization of warehouse inventory

-

Proactive identification of production times and critical issues

What does production scheduling involve?

Production scheduling software, also called APS (or Advanced Planning and Scheduling) is used within smart factories to reduce manual effort, reduce and eliminate the variables that affect the delivery times and inventories and have control over the production phases in processing, completed and completed.

You can easily plan all your business resources through visual management solutions and promptly reorganize the processing steps in case of need.

Your production system must be optimized in all the processes that make it up, especially if delivery times are increasingly tight. The main theme therefore remains flexibility and competitiveness in terms of managing needs. The software interested in production scheduling must therefore provide an excellent user experience and a speed of response useful to optimize the time available to the decision maker.

EXPERIENCES